Page 1 of 1

Differential oil measurement

Posted: Wed May 06, 2020 8:20 pm

by TheSaintDiscJockey

Today, I changed out the oil in my T differential. The Ford manual says not to overflow. About an 1 1/2" is about right below the import hole. I used a white clothes hanger end to measure. There has to be a better way? Mine is a 1920 T. Thanks all!

Re: Differential oil measurement

Posted: Wed May 06, 2020 8:48 pm

by Kerry

Yes there is a better way, for a start your T should have the filler plug 1-3/4" below the centre line which means since 1918 the oil is filled to the height of the filler plug. The 1-1/2" below the filler was pre 1918 except for the Canadian T's which started the lower plug in 1915.

Re: Differential oil measurement

Posted: Wed May 06, 2020 9:28 pm

by DHort

I just use the little finger on my left hand. Put it in the hole and bend it a little to see if I can touch the oil. Works great.

Re: Differential oil measurement

Posted: Thu May 07, 2020 3:28 pm

by Altair

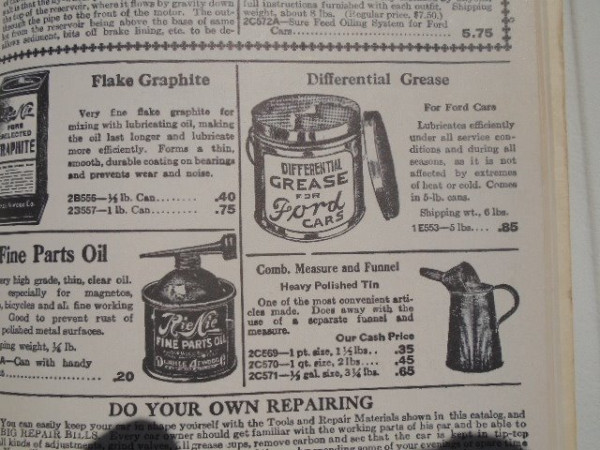

The issue of differential lubrication comes up from time to time, how much, method of measuring, type of oil and weight etc. All the documents and manuals I have read going back into the early teens have never mentioned oil as a lubricant for a T differential. Grease or a compound is mostly mentioned, a compound consists of at least two parts. In some of the parts manuals the differential plug is referred to as a grease plug and in others and oil plug. The differentials were never designed to be drained. The differential housings were never designed to seal oil (felts will not seal oil) In some early automotive books #2 grease is mentioned as the lubricant and in a 1920 edition of Western Auto Supply differential grease was sold for Ford differentials.

. The various methods of measuring the oil level and the type and weight of the oil is dependent upon the individual as there is no factory method. I have a 1926 model and there are no oil seals in the outer axles, oil can and will migrate out the ends of the axles there are many stories about this problem. There are many methods used to seal the outer axles some successful and some not so. I personally lean towards a creamy

non-flowing grease a #1 - 1.5 weight. I found the grease at a marine store where it is used in the leg gear box of a large out board motor. I tested the grease in the hot sun where I pointed the grease like an ice cream cone and let set, it sagged some but would not flow. Heavier greases stayed firm and the heaviest oils I could find all flowed. The earliest books I could find indicated #2 weight grease, however #2 appeared to be too heavy. When I disassembled my factory differential it was filled with a relatively heavy grease (like #2 weight) and the crown gear had cut a swath through it and I question the quality of the lubrication. I still feel grease is correct method however with some reasonable attention to the weight, creamy and non flowing.

Re: Differential oil measurement

Posted: Thu May 07, 2020 4:27 pm

by Norman Kling

You need the oil to flow because it lubricates not only the gears but the inner bearings and thrust washers. 600W is very thick and works with the original type rear axle but with a Ruckstell 90 or 120 is better because it has to work its way into the inner carrier to lubricate the planetary gears and pins.

Norm

Re: Differential oil measurement

Posted: Thu May 07, 2020 5:42 pm

by TheSaintDiscJockey

Many thanks for the responses. Incidentally, when I mentioned oil in my initial question, I was actually referring to 600w, which I used.

Re: Differential oil measurement

Posted: Thu May 07, 2020 6:55 pm

by Mark Gregush

Once the flowable grease get inside the works, it's going to take a while for it to flow out. This rear end has been sitting up right for a couple of months and maybe in the 6 months I have had, turned the drives shaft less then two roatations. I wish I knew what type it was.