Page 1 of 1

Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 1:57 am

by rainer

My Touring 1916 is one of these where the entire body, including the firewall, has to be lifted for freeing the path to get the engine out.

First I thought that the sheet metal "funnel" between Engine hood and car body/firewall is an independent part, but this is wrong. The "funnel" is mounted to the firewall and cannot be removed. Meanwhile the screws for firewall brackets are removed (this was really a nightmare on starter side, I worked 1 hours on them, so I definitely will mount a steel bar with tapped threads before reinserting the engine. This bar I will hold with the first bolt towards the front, it is only a few centimeters away. I have seen this in another topic, it will for sure make life easier.

What thread is used on this screws?

So the suggestion for lifting the body a few centimeters is my only option. I will slightly loosen the rear bolts and remove the middle and front bolts as I was suggested in my other topic. Then I will insert wooden blocks to keep it lifted until the engine is reinstalled.

Any idea where and how to lift the body? What weight will the body roughly have? 200 kg? Less? More? Where is a good point to attach the car jack to the wooden frame base for lifting?

Re: Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 10:13 am

by babychadwick

Try removing the starter first. Don't forget to remove the bendix before pulling the starter. Once the starter is off it can usually be tilted up allowing the pedals to get under the firewall. I just pulled my speedster engine and it needed to go in and out at about 70 degrees to work the pedals around. Not the same but a tight fit. If you drain your oil first and put in after it wont maks as much of a mess.

Re: Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 11:39 am

by speedytinc

I recently pulled a motor on a 15. Remove steering gear. Loosen the fire wall to body bolts & the hood former slid up & off. Remove firewall bolts & F/W brackets to frame bolts. Lift off the F/W. There was no need to lift the whole body.

Re: Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 11:44 am

by TWrenn

Well just as I tried to post practically the same advice as speedy...it got bummed from his as we must've hit the submit button at the same time! So Rainer...there you have it...two guys did the same thing on idea tidal cars to your 16, without raising the body.

Re: Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 11:47 am

by Mark Gregush

What thread is used on this screws? 3/8 X 24

The shield was just screwed onto the wood firewall.

https://www.modeltford.com/item/3638E7.aspx

When I reinstall my engine in the 1925, I too am going to make a threaded steel bar, but for the pan mounting. I snapped one of the through bolts on the starter side off, just long enough that I couldn't get the wood block out, so had to pull the hogs head. I am done screwing around with that bolt every time an engine is pulled or installed on starter type engines.

Re: Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 1:11 pm

by Steve Jelf

Oh yeah, the dash shield. I forgot to mention that. It's attached to the firewall with three little wood screws. I don't remember the size, but they have to be pretty small to fit the little holes in the shield.

Re: Lifting the body from metal frame ?

Posted: Sun Aug 22, 2021 4:29 pm

by Corey Walker

I know this isn’t a T but I use this method for lifting bodies. I’ve used it on my 14 runabout and an Overland Model 91 touring body and this Overland cut off body. I tie one end of strap to a rafter then under the body. I lift the side of the body on the opposite side and have the loose end over the rafter. After I raise it I pull the slack and tie the end to the next rafter. Then I raise the other side of the body. Then back to the other side, raise up, take out the slack and tie again. Repeat until it’s as high as desired.

Re: Lifting the body from metal frame ?

Posted: Mon Sep 06, 2021 9:54 am

by rainer

Hello and thank you so much for all your kindly help.

I did it exactly as described, I had to unbolt the "firewall" brackets, lift the upper chassis, ... I immediately found out that removing the coilbox was also needed. I used a long belt looped multiple times through the opening between cylinders 2+3 and lifted the engine there. This allowed me to get the engine into the right angle to lower the pedals sufficiently.

Then I had to build an adapter plate. I made it of 8mm sheet iron with welded-in pins (in distance of 4 oil pan screws). A lot of work, but perfectly now.

So the current status is:

I got out the engine, removed the Hogs-Head and Oil Pan, replaced the entire High Speed Clutch, replaced it by a new one (now original steel clutch), reapplied and checked internal securing wires, ... So the engine is currently still without oil pan, but ready for mounting the oil pan..

I will try to attach a few pictures.

I really wonder what this former owner did. There was a modern clutch inside, with 9 inner clutch disks (something similar to Jack Rabbit). But the clutch assembly was only 25mm instead of 27.5mm (as my steel clutch is), the clutch ring is only 25.5 mm high (including the pins), so in total, the pins slipped out of their holes while the entire clutch was actually unused (still rough friction surfaces), while clutch fingers in addition had 10 mm space(!) on their tips to the sliding ring. Now all measurements are correct and the clutch is operational (so I assume), the pins on clutch ring are almost leveled with the flange's holes when fully spring loaded and the spring is compressed to 50mm length.

Now I know every detail of my Lizzy.

Next will be closing the engine, hope there is no leakage in the oil pan when I start it again.

Re: Lifting the body from metal frame ?

Posted: Mon Sep 06, 2021 10:34 am

by rainer

It is really strange how to put pictures in ... Hope it works this time.

Here a picture of my garage. In the background you see Lizzy, in foreground the disassembled engine. The engine crane is standing in front of Lizzy. It is not the hook visible in foreground.

- My garage

My self made engine adapter plate. Material 8mm sheet steel.

- Engine adapter plate

Here the engine is turned upside down on my motor stand. Just a question of interest. I can see a bolt besides the upper eye of every connection rod. Is the upper eye clamped strong to the stud crossing the piston (does this stud move inside the piston's bore), or is this bolt used for adjusting the radial play of upper eye? Three bolts were secured with a very loose piece of wire. One of them with COPPER wire. One bolt was not secured at all. I re-secured all of them properly without turning them.

- Engine on motor stand, upside down

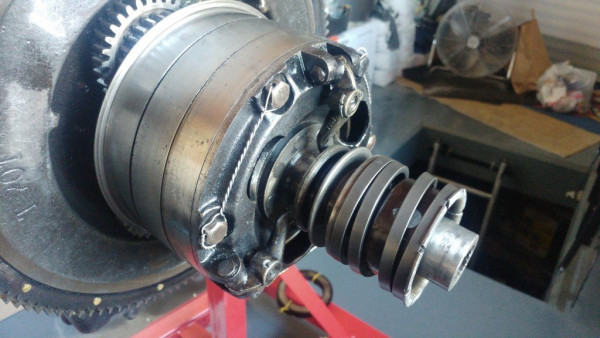

Here the ready-assembled gearbox end (without oil pan and hogshead mounted). Hope the securing wire is done well.

- Reassembled gearbox-end with Highspeed clutch

Re: Lifting the body from metal frame ?

Posted: Mon Sep 06, 2021 10:41 am

by Original Smith

I actually did have to lift the body on my '13 touring to get the GAS TANK out. It will not come out the top. Bad design. I lifted the body by the four top irons. Of course I had to remove all the body bolts, and a number of other things to do it. I believe there were five different body makers in 1913. I wonder if they were all that way?

Re: Lifting the body from metal frame ?

Posted: Mon Sep 06, 2021 10:49 am

by rainer

Indeed, the body was/is mounted in a very poor way.

So much has to be unmounted to access the gas tank or the engine.

Meanwhile I will for sure use steel bars instead of nuts to mount the splash-board holders. It was a nightmare to even remove these bolts, I don't want to think about how to get them in again. Luckily I own meanwhile a complete set of tapping tools for inner and outer imperial threads, so I can make such ones.

Can somebody tell me what is placed between rear engine holders (riveted to the oil pan) and steel frame?

Looks like very bad rubber to me, but I am unsure. Seems this 5mm material shall protect the steel frame from abrasion.

Same with radiator mounting screws. Looks like old carpet below the radiator mounts. (Brass radiator).

Re: Lifting the body from metal frame ?

Posted: Mon Sep 06, 2021 12:33 pm

by Scott_Conger

Rainer

good that you mentioned the wrist-pin bolts!

you do NOT want wire through them as it will flop around and eventually fatigue and break. While you can get at them, remove the wire and insert cotter pins through the bolt heads and bend 1 leg of the pin so that it is against the rod...this keeps the bolt from backing out.

Re: Lifting the body from metal frame ?

Posted: Mon Sep 06, 2021 12:47 pm

by speedytinc

rainer wrote: ↑Mon Sep 06, 2021 10:49 am

Indeed, the body was/is mounted in a very poor way.

So much has to be unmounted to access the gas tank or the engine.

Meanwhile I will for sure use steel bars instead of nuts to mount the splash-board holders. It was a nightmare to even remove these bolts, I don't want to think about how to get them in again. Luckily I own meanwhile a complete set of tapping tools for inner and outer imperial threads, so I can make such ones.

Can somebody tell me what is placed between rear engine holders (riveted to the oil pan) and steel frame?

Looks like very bad rubber to me, but I am unsure. Seems this 5mm material shall protect the steel frame from abrasion.

Same with radiator mounting screws. Looks like old carpet below the radiator mounts. (Brass radiator).

Pan arms sit directly on the frame. Radiator has 2 leather pads.

Re: Lifting the body from metal frame ?

Posted: Tue Sep 07, 2021 2:56 am

by rainer

Pan arms sit directly on the frame. Radiator has 2 leather pads.

Thank you. How thick should this leather pads usually be? 5 mm ?

I thought about using black EPDM pads. As they are invisible ...

I have no leather at hands.

Re: Lifting the body from metal frame ?

Posted: Tue Sep 07, 2021 3:03 am

by rainer

Hello, Scott_Conger

Rainer

good that you mentioned the wrist-pin bolts!

you do NOT want wire through them as it will flop around and eventually fatigue and break. While you can get at them, remove the wire and insert cotter pins through the bolt heads and bend 1 leg of the pin so that it is against the rod...this keeps the bolt from backing out.

You are so right, this was the first I thought (about wearing out of this wires), too. But I used safety wire and tightened it strongly, so no flapping.

Though, your suggestion with cotter pins is

definitely lots better, I will follow your advice.

The hole through the bolt head goes everywhere almost parallel to the piston stud (whatever it is correctly named). So I will insert the cotter pin, and bend one end around the bolt head (clockwise) to prevent the pin from rotating, while the other end will be bent in approx. 90 degrees until it touches the rod. Did I understand correctly?

Rainer.

Re: Lifting the body from metal frame ?

Posted: Tue Sep 07, 2021 10:44 am

by Original Smith

The radiator pads are thick. I'm sure Lang's probably has the correct thickness. I got mine from Regan when he was still in business.