Page 1 of 1

Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 5:35 am

by Rata Road

I'm in the process of an engine swap and both cars have a block of wood under the trans mounts inside the chassis rail.

What a pain as the vertical bolt cant be removed with the wood in place. I manage to chisel then smash the wood away in the first car after an hour or 2 but was impossible to do in the 2nd after a frustrating period however I managed to pry the mounts over the bolts in the end.

I would like to save the next person grief and leave them out. The trans bracket sits steel on steel anyway, what are these blocks meant to do?

Has anybody tried a layer of hard strong rubber between the mounts and the top of the chassis rail?

Thanks

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 6:29 am

by Humblej

Wood blocks are there for a reason. Pre 1926 ears are prone to work hardening and breaking over time, many a pre 1926 engine oil pan I have seen have a broken or cracked ear. Given the failure rate of ears I would not deviate from the Ford recommended mounting, using the wood blocks, horizontal bolts snug, vertical bolts tight, cotter pins, castle nuts, the whole 9 yards. That being said, the Ton Truck engines used a different mounting method. No wood blocks, no horizontal bolts, and a spring like the radiator mounting spring on top of the ear. I have studied the TT engine wood block drawings at the Benson Ford Research Center and found that the early TT engine mounting used the same method as the car engine mounting at first but with a larger block due to the taller frame rail, then eventually eliminated the block and horizontal bolt and added the spring on top of the ear. Even with that change to mounting, my 1924 unrestored TT has a broken ear too.

Unlike a conventional car that has engine mounts that are rubber to isolate the engine from the chassis, the T engine oil pan is actually part of the suspension and ties the front and rear wishbones to the chassis. The suspension forces, plus the frame twisting, plus the engine vibrations, all place loads on the oil pan ears.

TT engine mount as found on my 1924 Ton Truck.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 8:47 am

by TXGOAT2

I believe the wood blocks are important. My car does not have them, and it runs just fine, however, it has a balanced engine and is generally in top shape. The car has minimal vibration, and most of that is felt in the steering wheel. Very little to no vibration is felt at the pedals. That said, I believe that replacing the blocks would help stabilize the rear axle and give slightly better tracking over irregular surfaces, and that it would prevent excess strain on the pan ears under the same conditions by limiting deflection. Using stiff rubber might be a better choice than the wood blocks. A block of the same dimensions as the wood block but made up of pieces cut from tire sidewalls and glued together might give good results. A block made with sidewall rubber would allow some limited movement, prevent squeaks, and the fabric/rubber material would be very durable. The rubber would limit movement, yet keep some pre-load on the ears. In the case of a TT, I'd think blocks made up of sidewall rubber would do a better job than the wood, giving a snubbing effect while allowing some yield. I bought a set of wood blocks and the associated bolts, but of course they won't go in place without a fight. I don't think driving them in place is a good idea, since they are obviously not meant to be tight. I'm going to try shaving them with a rasp until I can just tap them into place, then install the hardware and see how the car behaves. I expect it will track just a little straighter. I doubt if vibration reaching the passenger area will be much affected, since it is minimal to begin with.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 9:40 am

by DanTreace

Ford used that method of engine mount, as the design is a 3-point suspension, for the lightweight twisting frame ability to meet the requirements of the T.

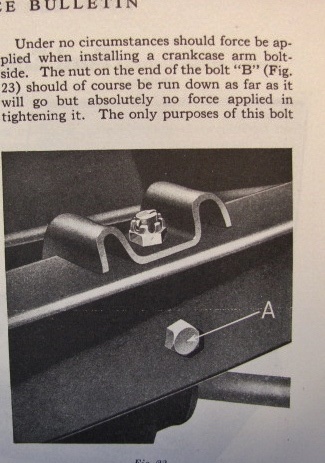

Leaving out this important block is IMO detrimental to the design. Note this original block removed, you can see the imprint of the crankcase arm, showing that it is giving support as the engine that moves during braking and forward motions, so a semi rigid support is needed. Wood does that job, these blocks are hard maple.

Without the wood blocks, there would be a large gap between the crankcase pan arms and the frame channel void, putting way to much stress on the pan arms.

The reason to not super fasten tight that long bolt is the wood block is doing its work, sandwiched firm between the frame channel and the crankcase arm, the bolt just keeps the shifting to a minimum.

- 311945.jpg (95.33 KiB) Viewed 4667 times

Sure it can be frustrating to drive that block in place, like it is to install any of the factory parts, but Henry wouldn't have designed it that way if it wasn't important!

- IMG_2842 (900x675) (780x585).jpg (86.25 KiB) Viewed 4667 times

Besides, when done, you can tell observers that your Ford has wood spoke wheels, and also wood engine mounts![/b]

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 10:46 am

by Norman Kling

Also remember that not only the torque of the engine, but also the force on the ball joint from the front and rear axles as well as the torque applied when the transmission brake is applied. All these cause some flexing of the ears. The wood blocks will keep them in line from side to side.

I have found that I can put a bit of duct tape on a box wrench and push it down on the nut inside the car and then turn the head of the bolt from the outside. If the bolt and nut are placed in the straight up and down position, the cotter pin can be placed. It doesn't need to be bent all the way around. Just enough to keep it in place. The wood block can be tapped into position from either front or back with a rod, such as a socket extension. it can also be tapped out the same way. It should not be so tight it has to be chisled.

Anyway, a little hard on the left side where there is no door and also the starter, but it can be done.

Norm

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 1:44 pm

by TXGOAT2

Another reason to put the wood blocks, or something, in the motor mounts is to keep the sharp edge of the motor mount ear from contacting the inner edge of the frame flange. If this is allowed to happen, the normal movement of the engine will tend to cut a notch in the frame flange, which in turn will lead to cracking of the frame.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 3:31 pm

by Chris Bamford

A couple things I have found that make the installation of these wood blocks and fasteners easier:

Use a pry bar of some sort to move the pan ear and frame apart a fraction of an inch. This makes it far easier to tap the blocks into position.

Some years ago I ditched the cotter pins and castle nuts and switched to stover-type self locking nuts. I am, as a rule, very keen on period fasteners throughout, but practicality rules supreme here.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 4:17 pm

by RGould1910

Would blocks serve a purpose if they are a snug fit. Those I have purchased from the parts vendors are so loose they provide no protection.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 4:47 pm

by Rata Road

I dont have time to make another parts order from the states as the plan is to refit both engines today so it looks like I will be making some blocks myself.

Most of the blocks I knocked out were a soft wood, looked like pine to me. I do have some hard wood lying around so looks like I will be doing a better job than previous.

So what I'm reading is the vertical bolts are tight but the sideways are just firm.

How about I refit the engines, refit the vertical bolts and tighten them up and refit the sideways bolts just firm with no blocks (allows me to move one car into another shed on my place) and then make and fit the blocks later in the week when I have time. Should be fine if there is no road test before blocks fitted?

Thanks again for your excellent feedback guys, always learning.

Kevin

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 5:07 pm

by John iaccino

I think I have found original wood blocks in my stash of parts. I will try to find them and post pictures.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 6:03 pm

by Rata Road

Thanks John

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 6:22 pm

by Oldav8tor

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 7:39 pm

by Jerry VanOoteghem

Rata Road wrote: ↑Sun Jun 05, 2022 4:47 pm

How about I refit the engines, refit the vertical bolts and tighten them up and refit the sideways bolts just firm with no blocks (allows me to move one car into another shed on my place) and then make and fit the blocks later in the week when I have time. Should be fine if there is no road test before blocks fitted?

Thanks again for your excellent feedback guys, always learning.

Kevin

If all you're doing is moving the car to another shed, you could leave out the sideways bolts and put them in when your wood blocks are ready.

Re: Is there need for block of wood at trans mounts?

Posted: Sun Jun 05, 2022 10:26 pm

by jiminbartow

The notch at the base of the block on the passenger side is where the fuel line for the under seat gas tank is routed to prevent the fuel line from bouncing around the inside of the chassis channel. Jim Patrick

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 8:17 am

by TXGOAT2

I Installed the wood blocks in my '26 with starter car yesterday It took about an hour and a half. With a helper, it would have taken less than half an hour. The blocks fit tightly. I had to pry the frame away from the pan arm slightly as I tapped the blocks into place with a light hammer. The bolts went in easily. I'm not pleased with how tight the nuts had to be to get a cotter pin in place. I decided to split the cotter pins to allow the nuts to be a little looser. I think they're still on the tight side, perhaps due to paint or powder coat on the frame. I believe they will loosen quickly as the car is driven and the wood beds in. As far as performance, the car seems to have a tighter feel, and seems to track a little better on rough roads. I can't say that vibration is reduced, but it was already about as minimal as a T with a stock crankshaft can be. Using high quality self-locking nuts instead of the castellated nuts would make it easier to adjust the bolt tightness as needed. I get a distinct impression that having the blocks in place stabilizes the front axle assembly when driving on poor roads.

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 9:11 am

by Ken Buhler

This has come up many times. Look back at why Herman Kohnke said to not use them.

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 9:49 am

by George House

Ken, I tried to search for Herman’s advice not to use the wood blocks under the pan ‘ears’ but came up empty. Can you please provide specificity ?

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 10:23 am

by DanTreace

George House wrote: ↑Mon Jun 06, 2022 9:49 am

Ken, I tried to search for Herman’s advice not to use the wood blocks under the pan ‘ears’ but came up empty. Can you please provide specificity ?

Here is that post:

By Herman Kohnke on Tuesday, February 22, 2011 - 01:54 pm:

We have for 40 years only used the top frame bolts. The side bolts do no good, only harm. If the arms are held tight, or loose, with the side bolts, and you go over any uneven ground, where the frame will twist, it can crack, or twist the arms, but what you don't see in the twist it puts on the ball cap, and the rest of the pan. Herm.

Just as much experience, have driven, restored and owned over 12 Model T's in 50 years, always have used the wood block between the frame and crankcase pan arms. No cracks also.

Photo off this forum, no side bolts or wood blocks......just picturing the results of non- Ford assembly.

- 88815.jpg (63.18 KiB) Viewed 4251 times

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 11:06 am

by John iaccino

I think these are original wood blocks for the tranny mounts. What do you guys think?

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 11:14 am

by TXGOAT2

I believe that Ford would not have hesitated to delete the blocks, bolts, and the costs and labor of making, stocking, and installing them if they were found not to be important. They are meant to limit side-to-side movement of the engine assembly in the flywheel area. They are not mean to be a solid, inflexible joint, and they aren't. The oil pan assembly is a stressed member in the Model T design. It has to absorb engine torque forces, engine vibration, thermal stresses, stresses arising from frame flexing, road pounding delivered directly to it via the front wishbone, and considerable forces delivered from the rear axle that result from drive forces, road pounding, and braking stresses. All this on top of supporting and locating the engine and transmission. The wood blocks divert much of these various loads directly to several squuare inches of the frame side members, rather than concentrating all of them in the pan ears at and near the point where the upper mount bolts attach to the frame flanges.

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 11:15 am

by TXGOAT2

Never seen any like those.

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 2:29 pm

by Rich P. Bingham

Yes, you need the blocks.

I'm perennially amused at the number of T owners who know better than its manufacturer of nearly 20 years what is necessary for its care and feeding. The thing is, the beast is tough enough to withstand most deletions, additions and modifications. "It don't hurt the runnin' of it none !"

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 2:55 pm

by Jerry VanOoteghem

Rich P. Bingham wrote: ↑Mon Jun 06, 2022 2:29 pm

Yes, you need the blocks.

I'm perennially amused at the number of T owners who know better than its manufacturer of nearly 20 years what is necessary for its care and feeding. The thing is, the beast is tough enough to withstand most deletions, additions and modifications. "It don't hurt the runnin' of it none !"

Agreed 100%

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 3:32 pm

by DHort

Kevin

I have always used a brass drift or punch to get those wood blocks in or out. The hardest trick is then to get the cotter pins in the castle nuts. Might want to grind off the bottom of the castle nuts so the horizontal bolt is not too tite. If Ford thought they need to be there, I will keep them there.

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 3:37 pm

by RajoRacer

That's a really good place for a nylock nut !

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 4:06 pm

by Scott_Conger

Steve, I totally agree

that said, though, I cannot for the life of me understand all the angst over putting in a cotter pin and giving it a gentle tweak to keep from coming out. There are a number of places which seem to involve struggling while working on the car, but this has never been one of them...at least for me, it hasn't

Re: Is there need for block of wood at trans mounts?

Posted: Mon Jun 06, 2022 4:46 pm

by George House

Thanks Dan for Herman’s info and thank you Tim Juhl for the dimensional diagram of these hard wood blocks. I shall now endeavor to build 7 pairs for my Model T s. I am now persuaded they’re necessary...

Re: Is there need for block of wood at trans mounts?

Posted: Tue Jun 07, 2022 9:32 am

by RGould1910

In defense of Herm's approach, I believe the side bolts are not tightened down and therefore allow a bit of movement. I suspect they are there mainly to prevent the block from moving.

Re: Is there need for block of wood at trans mounts?

Posted: Tue Jun 07, 2022 9:58 am

by TXGOAT2

I believe that is correct. The side bolts only need to be tight enough not to rattle. The 1/2" hole in the blocks is larger than the OD of the bolts to allow slight movement. The blocks also have clearance between the top of the block and the upper frame flange. //I had some concern about how tight I had to get the side bolts to allow placing the cotter pins when I recently installed new wood blocks on my car. As I expected, about 100 miles of driving has caused them to loosen to the point that they can easily be turned with a 6" wrench. Another 100 miles and I should be able to install the cotter pins in the normal manner without any worry about overtightening the bolts. The blocks show no sign of any movement.