Page 1 of 1

Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 4:35 am

by Rich Eagle

Next on the list was to fix a flat on the Speedster and one for the Coupe. The tube testing tank I made several years has faded just about right. I filled it with water and looked for the leak. At almost 75 years old I questioned the wisdom of dismounting and mounting tires in 95° heat. It turns out that the heat on the tires makes it easier to work with. Working in the shade and resting as needed worked very well.

The tank has a lid that works well as a workbench. The bubbles easily show it's the tube and not the stem.

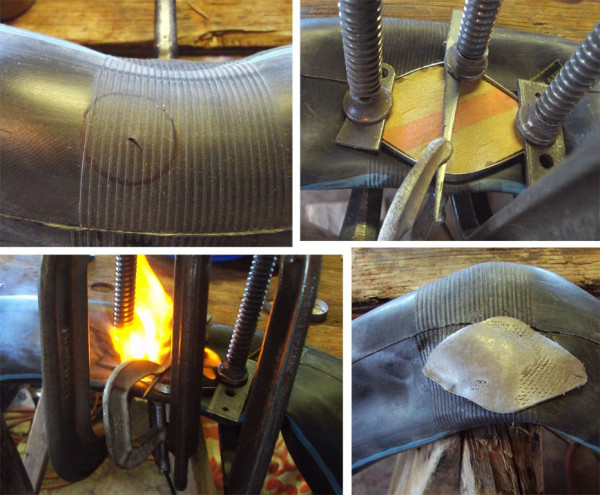

The rubber cement always seems to dry out by the time I need to patch a tube. However, I found Some Match-Patch vulcanizing units that were sealed since new. I'm always ready for an adventure so I clamped up one of them for this fix. It lit up nicely and I let it cool while I cleaned up the tire and rim. When I unclamped the tin cover the patch looked kind of ragged but was sticking over the area where the leak was.

Retesting showed no leaks in the tube. All was ready to mount the tube, flap and tire to the rim. I was feeling pretty smug about how well this had gone. That is always a big mistake. The tire mounted well except a place where the bead didn't quite push into the clincher. After mounting about a hundred tires each one is a little different. I thought I remembered putting a little more air in and having the bead pop into place. Not so this time. A little too much air and KABLOOM!!! The tube blew out past the bead. The exploding tube is something I have experienced a couple times before. The first time I was hand pumping a very used tire up. I remember the cord threads started popping and a red innertube came out of it getting bigger and bigger. I naively thought "this is interesting" before I could really asses the situation and all too soon the deafening blast was in my face. At any rate I will miss that tube but can use the brass stem in another one.

I was a bit disoriented but managed to find a tube that was tucked away at the bottom of the Speedster trunk. It had survived 30 years or so and looked like one of the good ones. It went in easily and I mounted the unit to the spare tire rack. I drove to get gas and some new rubber cement and patched the Coupe tube and mounted it up. That brass stem shows some wear from the rim like all the old ones I find. That tube may be one of the ones I bought in 1964. They have served me well. While the cement is fresh I will patch all the tubes I can find and mount up several tires for future use.

That's the plan for tomorrow. My ears are still ringing like a dial tone and everybody sound like they are talking under water but that usually goes away in a day or two. Model T work can be exciting and rewarding.

Rich

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 4:40 am

by Rich Eagle

These are the Match-Patch vulcanizing units. I'll try another some day.

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 8:07 am

by TXGOAT2

We had Monkey Grip hot patches. Dad would scratch the surface of the fuel "biscuit" and light it with a wooden match or a Zippo. The burning material made a nice sizzling sound and gave off a pleasant aroma. The diamond-shaped red rubber patches worked very well, as did the crab-like cast iron clamps specially-made for holding the metal patching assembly on the tube.

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 8:09 am

by TXGOAT2

We'd always buff off the little ridges and seam lines on the tube before applying the patch.

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 8:54 am

by Steve Jelf

When the tube escapes and explodes it's quick. By the time you realize what's happening it's too late to stop it.

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 9:01 am

by Allan

Heat set patches are used to mimic vulcanizing on rubber tubes. I am not sure if they will work on butyl tubes. That's where the stick-on patches come into their own. It's been a long while since I have seen rubber tube for T's. I have two red rubber ones on my cars, but have lost track of just which car they may be fitted to.

Allan from down under.

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 10:09 am

by Rich Eagle

I apologize. I just did the math and I'm only 74 years old. I had said "almost 85". Correction has been made.

We old folks deserve a little slack.

It's fun to hear the comments.

Thanks

Rich

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 10:11 am

by TXGOAT2

We used them well into the 1960s. In those days, "tough butyl rubber" was a selling point in tire advertizing. I don't think natural rubber ever made a full comeback after WWII. Tire stores smell different than in days past. I don't know if modern tires have any actual rubber content.

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 10, 2022 10:24 am

by John Codman

I would not have installed the tube with the not-too-nice patch. I hate doing the same job twice - The patch will be perfect or I wouldn't install it. I demand the right to be angry when something fails. If the patch didn't look perfect, I would not have that right.

Re: Fixing flats and the best laid plans...

Posted: Mon Jul 11, 2022 3:15 pm

by Rich Eagle

I totally understand that John. I know some who wouldn't install a patched tube at all. They would only put in a new tube.

Yesterday I managed to repair and install 5 tires and tubes. Having all the tools and supplies out makes it faster and easier. Some rolls of patch material were found a while back and work nicely. I also rescued 4 innertubes and will get them inside tires soon. Two leaky rubber stems were replace with brass stems. I have retired 3 of my Firestones that I bought in 1964. They have given good service on various cars for 58 years. The most recent was the Rusty Coupe. The sidewalls, tread and beads are not fit for full pressure any more but will serve fine at 30 lbs for yard equipment. They cost me $46 a piece when new but I think they were worth it. I also have a set of Wards Riverside's that Rich B. bought about the same time. They have seen more indoor service and will be used as needed in the future. Those old tires and tubes were as good or better than any I have purchased since. I also took the time to better fix my air hose. It's two inches shorter but I believe I can get by with it. One rim had an extra hole in it. Perhaps to fit a Chevy or other valve stem location. I have had to put a "boot" in that location to use it. One old patch has cracked with age while hanging in the rafters.

I did several repairs like this a few years ago and ended up with 8 tubes hung up and not in tires. The old ones were in good shape but more recent ones had cracked where they kinked while hanging. Shown here they are a Coker Tire Co and an Antique Tire Co (Taiwan). I'm sure these gave hundreds of miles of good service when new but didn't like the open air in later life. Maybe I'll try to patch them while I have the cement and patch material. Not in something I drive though. The materials are different and sometimes patches don't hold.

I learn a lot in doing these tasks and am passing on what might be helpful to others.

Today I'm taking it easy from the sun and the exertion. Maybe tomorrow I will tackle some more.

Rich

Re: Fixing flats and the best laid plans...

Posted: Tue Jul 12, 2022 4:23 am

by Allan

Rich, your rim with the extra valve stem hole is most likely a Hayes made rim for Ford. The second hole near the lug indicates it may have been fitted to a Chev. If it was a Chev rim, that lug near the valve stem hole would be slotted to drop down over the adjacent rim bolt. The Ford rims are approx 1/4" narrower then a T rim, so there is another difference to check out.

When I restored my 1915 tourer, I fitted it with a fully restored set of Hayes wire wheels. When fitting the rims and tyres on the final put-together, I discovered that one of the wheel felloes had been drilled with an extra hole, obviously to fit a Chev rim at one time. That hole was never restored. I put a plastic plug in it and painted it by hand to disguise it.

I have had a love/hate relationship with Chev rims ever since.

Allan from down under.

Re: Fixing flats and the best laid plans...

Posted: Tue Jul 12, 2022 6:19 pm

by Rich Eagle

Well I'm beginning to dislike this one. That tube didn't past the overnight test. It was flat this morning. It's hot and I don't have that little bit of extra energy today for it. I'll report anything interesting when I tackle it.

I do have some rubber cement to use up before it goes bad.

Thanks

Rich

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 31, 2022 1:19 pm

by Rich Eagle

I am slowly gaining ground. When I walked by the Coupe the other day it had another flat. That tire had been fine for a few years. Testing the tube showed that pushing the valve stem one direction produced bubbles. I will install a brass stem. Another one I patched recently went flat. Bubbles immerged from a wiggly rim lug. There must have been a sharp edge or a pinch there. I have patched it and installed a flap. Flaps seem to be good the more I work with these.

Somehow mounting and dismounting tires has been enjoyable even in the heat. Even the rust, dirt and cracks. The tube test tank gives off cool moisture much like the grandkids splash pool. I guess I could have used it except the tank bottom was covered with mud and debris the other day.

It's easy to imagine the countless fellows in the twenties and thirties who changed tires day in and day out as a routine. Even in the 50s and 60s their black hands and darkened attire showed honest work and a kind of charisma. Many of the old garage workers and machinists were fascinating to me in appearance and as delightful characters. Youngsters nowadays probably don't see that much or have a chance to enjoy it.

Maybe it's not that charming to most folks but it makes doing these worthwhile.

Rich

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 31, 2022 1:41 pm

by CudaMan

Maybe I haven't done enough of them to get the full experience, but I can say that so far I have never found mounting or dismounting clincher tires enjoyable!

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 31, 2022 5:01 pm

by jiminbartow

That looks like the type of cut that can result from not having a flap that protects the tube from a rough rim. Here are the old “Camel” Brand biscuit type patches referred to earlier. They still work great. Jim Patrick

Re: Fixing flats and the best laid plans...

Posted: Sun Jul 31, 2022 9:47 pm

by Rich Eagle

The camel logo is as great as the patches.

I have been thinking Mark. Patching tires was on my list of aggravating tasks along with changing bands and a dozen others I can't recall right now. I'm not sure what makes it less miserable now. Maybe it's the cute bubbles in the water or the splendid colors in the bright sun. Being retired and doing these at my leisure is sure better than as an emergency along the road.

The tire I patched yesterday let out a big rip and I have it down again today. It was a small tear on an old fold and was pretty weak. Some have taken 3 or 4 try's so my average isn't so good. It is satisfying to be able to still do difficult tasks like this. I have become way more proficient than when these were new and I was a kid.

Some of the fun is in playing with the bridge washers and their nuts. Or the endless roll of rubber patch material. Being a cheapskate, the saving of 8 or 10 old tires and tubes seems worthwhile. I still chuckle that I am doing this on carpet my folks bought about the time I was born. Dad repurposed it to some other rooms later and then I put some of it out in their garage. It has followed me around and is now in my present garage. I played with toy cars on it as a toddler. Perhaps this second childhood is part of the satisfaction.

Re: Fixing flats and the best laid plans...

Posted: Mon Aug 01, 2022 7:19 am

by Loftfield

Back to your bad day: People make plans; God laughs!

Re: Fixing flats and the best laid plans...

Posted: Mon Aug 01, 2022 8:36 am

by Allan

Richard, i love your leak testing tank. It is likely much more user friendly tan the laundry tub I use, to my wife's chagrin! I do agree with Pat's tip that the little ribs do need to be buffed off for a patch of any sort to do its job. I got sick of doing this by hand with sandpaper/scratch pads, so I bought the proper mushroom tool the pros use. I use my battery drill to drive it. Being able to do it easily means I can do it properly without scrimping on the extent needed.

Allan from down under.

Re: Fixing flats and the best laid plans...

Posted: Mon Aug 01, 2022 11:59 am

by Norman Kling

A few months ago I installed a new tube in a 40 year tire! The tire was very hard to remove and replace on the rim, but with the help of my son, got it done. It is used as a spare on my car. It is a Riverside tire made in USA during the Viet Nam era. Not badly cracked because the car has always been stored inside without direct sunlight. The tires I drive on look identical, but were made a few years ago in Viet Nam. That is one of the talking points I use when showing my car.

Good luck on the ear ringing. The last time I fired a rifle was over 60 years ago, but my right ear is still ringing! I know it's in the ear, because my hearing is so good Only I hear it and no one else I have mentioned it to can hear it!

Norm

Re: Fixing flats and the best laid plans...

Posted: Tue Aug 02, 2022 7:38 pm

by Rich Eagle

Back at it again today I discovered one tube that had a leak in an old red patch. I may have put it on 30 years ago. Much of this nonsense is in the name of seeing what I can get away with as much as saving these tubes. Patching patches probably isn't the best but while this one is still holding I gave it a try. Using a tin from one of the old vulcanizing patch units and some gasoline I clamped and heated the new patch in place. My Camel quick cure tube gum 10-036 instructs me to "vulcanize for five minutes at sixty pounds steam pressure (307 F.)." "...cure 8 to 10 minutes at sixty pounds steam pressure." I'm guessing steam patching was popular at some time but can't find much on the internet. I'm sure some of the old books and manuals tell all about it.

For now a little heat and then some pressure seem like the thing to do. This patching gum works pretty well cold too. You can see how it worked around the patches after the heat and pressure. I am letting them sit overnight before putting air in the tube.

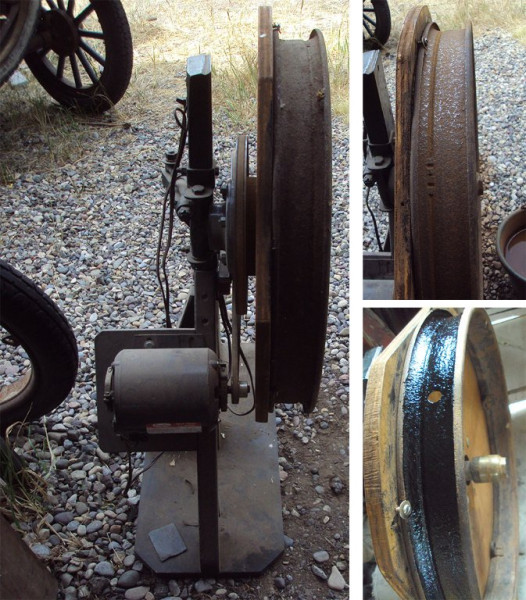

Having tires and tubes on the current rims I needed to find a rim for another good looking tire. I mounted a useable rim from the pile on my rotating stand and wet sanded a lot of dirt and loose rust from it. It turns about 50 rpm and eats a half a sheet of 80 grit in 15 minutes or so. This gets them clean enough for a coat of Por-15 or in this case a coat of tractor paint.

The swishing sound of the sandpaper and water is a bit like the air coming out of a tire. Low and behold, when I stopped the sanding I could still hear that sound. At breakfast a fellow told me it looked like I had a low tire on the Coupe. It was down to 25 lbs but got me home fine. I had parked near the air hose and filled it to 45 lbs. I had been cautious in riding on 35 lbs in these old tires for years but increased these repaired ones to 45 or 50. Filling the tire today was just too much for it and it ripped a 4" tear in it. That will be more than I believe is patchable today. I replaced it with a tube that has held air for several days. It has some cracks in creases and will let go at some point like the previously mentioned one. However they often last months or years before failing. I added a flap this time and will see how it lasts at 35 lbs. This tire is about 30 years old. It has a rim cut as 2 sets that I used on the Speedster got in them one year. That is when I started using flaps. They are much more flexible and easier to mount. But with the rim cuts I will use less pressure. They don't seem to get worse driving around town.

There is something new each day and I hope some of it has some value to relate to others. The story gets longer. The more I do the more I learn and can apply to more serious tires on the other cars.

Rich

Re: Fixing flats and the best laid plans...

Posted: Tue Aug 02, 2022 7:51 pm

by jiminbartow

Sprinkle baby powder around the inside of the tire and on the bead and rim to act as a dry lubricant that will assist in getting the tire onto the rim. Jim Patrick

Re: Fixing flats and the best laid plans...

Posted: Wed Aug 03, 2022 4:52 pm

by Rich Eagle

Yes, talc (talcum powder) is often used to great advantage in helping the tube move freely in the tire. With the Vaseline like stuff on some flaps and then testing the water tank I wonder about a sticky mess. I haven't tried it but I may. The 30 year old Firestones I spoke of are flexible and I can pry them off and walk them back on in a few minutes. That may be why they slid on the rims and got cut so easily. Contrast that to this stiffer old Riverside. It seemed the bead was going to tear before I got it stretched on today. I used bench weight on a sawhorse to hold one iron down. The stiff beads made getting the tube and flap in place more difficult but it is holding air now.

Again, hearing air escaping from one I had just patched was disappointing. It started with a small hole which ripped into a wider tear as I mentioned before. My tube gum patch let go. It's not so good for longer tears. I put a thicker round patch on it and will see how it does. I am learning as much from things that don't work as those that do work. I have two new inner tubes coming and will use them in the next two tries to go flat.

I believe I have 8 tires holding air from this ordeal. While not the recommended exercise I believe it is better than none.

I was thinking of making some more elaborate bridge washers this Winter. Schrader made a lot of different ones but I think this Dill looks like it would work well.

Thanks for sharing the fun.

Rich

Re: Fixing flats and the best laid plans...

Posted: Wed Aug 03, 2022 5:32 pm

by jiminbartow

When I changed over to new 21” Goodyear tires, flaps and tubes, I cleaned off the majority of the vaseline-like lubricant from the inside of the tire and flaps (there was no Vaseline on my tubes) with mineral spirits so the baby powder would not become a sticky mess. After the mineral spirits evaporated, I poured the baby powder in the tire and bounced the tire as I turned it so the inside was coated. I then inserted the slightly inflated tube and, over that, between the beads, inserted the flap, tucking the flap over the tube and under the beads and sprinkle more on the flap and beads before working the beads onto the rim with two tire irons. Works like a charm. Jim Patrick

Re: Fixing flats and the best laid plans...

Posted: Wed Aug 03, 2022 6:24 pm

by RajoRacer

Were you installing tires on split rims or wires ? You shouldn't need irons on drop center wires - I just mounted two by hand.

Re: Fixing flats and the best laid plans...

Posted: Wed Aug 03, 2022 8:32 pm

by jiminbartow

Mine were split rims and I couldn’t have done it without tire irons. The new tire beads were very tight. The first tire took me almost all day. By the fifth tire I was down to 30 minutes but still needed tire irons. My Hercules split rim tool worked great. In getting it ready to paint and while removing the thick layer of rust, I discovered some flakes of the original red paint, so instead of painting it black as I was intending, I painted it red. I was very pleased with the results. Jim Patrick

2ABF86F0-9034-462A-9CB4-DEBDDD1F1488.jpeg[/attachment

[attachment=0]D6977DF7-C793-4A60-B295-E8732CFD6CD6.jpeg

Re: Fixing flats and the best laid plans...

Posted: Wed Aug 03, 2022 10:00 pm

by RajoRacer

Appreciate the reply Jim !