Page 1 of 1

Commutator & Rotor

Posted: Fri Apr 26, 2019 9:25 pm

by ChuckLebeda

I have a 1921 coupe purchased five years ago from an estate. Trying to get it started this winter.

Cleaned electrical system from negative ground on frame through to the spark plugs.

My problem was went I went to start it, it backfired and would not start. To make a long story short, I pulled the commutator and the rotor was all twisted and destroyed. The commutator cap is brand new but the rotor appeared original. So ordered another rotor which I installed and had the same thing happened. Two rotors destroyed. Inside of commutator looks excellent, no damage. Attached is the picture of the cap; is this an Andersen cap and I am putting in the wrong rotor??? The cap has the contact points numbered. Any help on this problem would be greatly appreciated. Thanks! Chuck

Re: Commutator & Rotor

Posted: Fri Apr 26, 2019 9:54 pm

by Mark Gregush

Sounds like when it back fired because it was timed wrong or the lever was pulled down, the flapper caught on the contact and got messed up. You need to check your timing. It should be set to fire at No 1 compression just after the piston is on it's down stroke with the lever up. I have found in the past with Anderson timers, you need to watch where the lever is on start up. Sometimes if the engine rocks back they will pull the lever down. Some people love them some swear at them. I am the latter.

You may also need to at this point get the contacts inside reset, they may now be bent out of alignment.

Re: Commutator & Rotor

Posted: Fri Apr 26, 2019 10:54 pm

by ChuckLebeda

Mark: Is this cap from an Anderson timer??

Thanks for your info! Chuck

Re: Commutator & Rotor

Posted: Fri Apr 26, 2019 11:01 pm

by Mark Gregush

looks like it, show the outer side.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 12:10 am

by Mark Gregush

Might not be an Anderson, but to be sure show the rotor and other side. I can't think of any way that a rotor could be destroyed by back firing. If it was a standard timer with just contacts inside, the rotor would just roll backwards. If it is indeed an Anderson and you are trying to use a roller type, that would be an issue. You would need the flapper type contact.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 12:54 am

by HalSched

You will be surprised how much a new wire harness will improve the operation of the engine. As stated, with that cap U need a flapper, not a rotor. Make sure none of the wires or connectors are grounded because that would give you a backfire.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 12:57 am

by HalSched

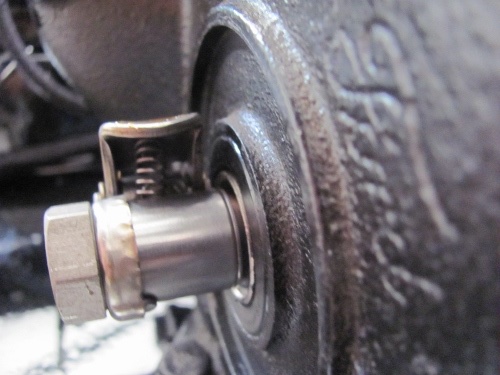

Closer look...That flapper looks like it has a "wheel". That's a good idea

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 10:57 am

by ChuckLebeda

Here is the side view. Needs an ANCO roller/rotor.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 11:02 am

by Mark Gregush

That still does not tell us anything. Need to see the insides.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 12:42 pm

by DanTreace

Anderson timer shell has arms inside, the rotor is a flapper, spring loaded.

- IMG_7115 (500x375).jpg (89.06 KiB) Viewed 6625 times

The common Ford style timer case has contacts imbedded in a ring, the rotor is a spring loaded roller.

Mixing the two is problem.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 3:28 pm

by ChuckLebeda

First time it was set up this way by previous owner and had never been run. Second time was my fault, should have known.

Fool me once, shame on you. Fool me twice, shame on me!!

Thank you all for your help.

Chuck

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 3:33 pm

by ChuckLebeda

Dan:

Did you use spacers between the rotor and the camshaft??

Chuck

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 6:31 pm

by DanTreace

Chuck

I have used the spacers before. Usually depends on the cam you have, some have shoulders a bit long or short. If too long you can get a rotor with more narrow cylinder. For most times, one or no spacers works. Check the need for spacers by testing the action of the flapper, once you fasten it firmly with the cam shaft nut. Test the flapper so it moves completely free. Any impingement on the front plate will cause the flapper to hang up. Use a spacer to place it away from the front plate.

Normally using the spacers won't interfere with the rotor pin, but....at times had to rat tail file the slot a tiny bit for the pin to fit in snug. The Anderson pin cap is unique, has a good raised edge to clear and retain the pin, and has a cutaway for the flapper action, (i.e. the flapper circle clip and axle) ; if you use a Ford std. pin cap without that cutaway, you can have the flapper hang open or closed.

Bit of high strength grease on the flapper, for lube against the case fingers. This view shows the raised edge over the rotor pin, and the cutaway edge, you can see the flapper axle is free to move, no pinching.

Re: Commutator & Rotor

Posted: Sat Apr 27, 2019 10:25 pm

by Mark Gregush

Don't know but there must be more to this story then what is being told. If you tried to run a roller(?) in an Anderson and the roller got wiped out twice, I am still going to say the timer will need service because changes are good the contacts are now bent out alignment. That changes the cylinder to cylinder firing time.

In your first post your not sure what kind it is then the jump to needing spacers? Are there some PM's going back and forth leaving the rest that are trying to help in the dark?