Page 1 of 1

throwing my belt

Posted: Sun Apr 16, 2023 12:34 pm

by chiporem

My 26 TT keeps throwing the belt off the fan and crank pulleys. The crank pulley is closer to the cases than the eccentric adjuster pulley at the top of the engine causing the belt to ride forward on the pulleys. With the crank pulley pinned in there's no way to adjust it out for alignment and I can't think of a way to pull the top pulley back. I have the eccentric belt adjuster at the top.

Am I missing something? Is there a way to adjust the bottom pulley out?

Thanks

Calvin

Re: throwing my belt

Posted: Sun Apr 16, 2023 12:49 pm

by Matt in California

Calvin,

I am following this post I have been having an issue with my belt coming off in the last few months as well on my 1926. It is not clear to me everything you are saying, but for me I have the tension all the way. The belt doesn’t seem over tight. But it seems to come off often.

I look forward to the advice of others.

Matt

Re: throwing my belt

Posted: Sun Apr 16, 2023 1:15 pm

by Adam

#1) The ‘26/‘27 belt tensioner gets tensioned AWAY FROM the commutator (turn tensioner counter-clockwise while looking at the front of the car) this moves the belt AWAY FROM the commutator.

#2) If the tensioner is all the way up, then the belt is too long or stretched and requires replacement.

#3) If the top aluminum pulley has no crown in the middle, or the crown is worn off center, then the belt won’t track properly.

#4) If the bottom pulley is loose, the belt may not track properly.

#5) If either of the pulleys are painted, the paint affects tracking and pull. This is a widely known fact among antique tractor and steam engine professionals.

#6) If the fan pulley bearings or shaft are worn, the slight tilt effects tracking.

Re: throwing my belt

Posted: Sun Apr 16, 2023 1:29 pm

by Russ T Fender

Played with that on my '27 many times and each time it seemed like I had solved the problem but it always came back. I finally added a belt guide and have not had any issues. There's a reason why they made them.

Re: throwing my belt

Posted: Sun Apr 16, 2023 1:32 pm

by Craig Leach

Hi Matt & Kalvan,

Have you guys tried the aluminum pullies the venders sell? They are wider & have a flange on them. The greater width seems to give the belt

more room to find it's happy spot to run in. I also have gone to polly groove belts. They can be a pain to match up but seem to last for years.

( Disclaimer ) The polly groove belts are not for show cars (they just don't look right)

Craig.

Re: throwing my belt

Posted: Sun Apr 16, 2023 1:46 pm

by Rich P. Bingham

Flanges on a flat pulley are unnecessary and may actually cause a belt to come off. Counter-intuitive I know, but the crown on the pulleys is what centers the belt. A flat belt will always "find" the high side; trouble with belts staying on is almost always caused by mis-alignment of the pulleys. Their axes must be parallel.

A model T's fan belt need not be as tight as modern V-belts running an alternator, AC, and other stuff. If it will turn the fan, it's tight enough.

Re: throwing my belt

Posted: Sun Apr 16, 2023 4:44 pm

by Craig Leach

I thought the issue was miss alignment?

Craig.

Re: throwing my belt

Posted: Sun Apr 16, 2023 9:23 pm

by chiporem

It is misalignment. The crank pulley is about a quarter inch further to the rear of the vehicle than the fan pulley. I'm asking if there's a way to move the crank pulley toward the front of the vehicle or if there's a way to adjust the fan pulley towards the rear of the vehicle. Again, they appear to be about 1/4" out of alignment.

Re: throwing my belt

Posted: Mon Apr 17, 2023 9:00 am

by Mark Gregush

chiporem wrote: ↑Sun Apr 16, 2023 9:23 pm

It is misalignment. The crank pulley is about a quarter inch further to the rear of the vehicle than the fan pulley. I'm asking if there's a way to move the crank pulley toward the front of the vehicle or if there's a way to adjust the fan pulley towards the rear of the vehicle. Again, they appear to be about 1/4" out of alignment.

The pulley on the crankshaft is pinned in place, so no there is no easy way to move it. Can you post some close-up photos of the upper pulley, esp the rear. It is possible something like washers have been added, moving the pulley to far forward.

Re: throwing my belt

Posted: Mon Apr 17, 2023 9:12 am

by Scott_Conger

Of course, it should not be misaligned, and that issue ought to be corrected. My guess is, though, that one or both pulleys lack any kind of meaningful crown. I say that because if they were both crowned as manufactured, the belt would still stay on with a 1/4" misalignment.

Re: throwing my belt

Posted: Mon Apr 17, 2023 9:17 am

by JTT3

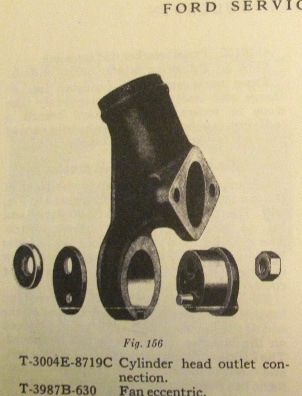

Does it have the 26-7 water inlet/ fan assembly? If so I seem to remember but could be wrong, that there were a few different styles produced with a difference in the proximity of the fan assembly toward the radiator. I do know that the way the fan cam was captured changed but I also believe that the proximity was different too.

Re: throwing my belt

Posted: Mon Apr 17, 2023 9:57 am

by Scott_Conger

John, the proximity change was only an extension of the pulley...the casting was extended forward to bring the fan closer to the thinner radiator...the remainder of the pulley is the same, including all of the mounting and seal areas. The other thing(s) you mentioned may have a bearing in the issue and I am not knowledgeable of those potential differences so cannot comment.

Re: throwing my belt

Posted: Mon Apr 17, 2023 3:40 pm

by chiporem

It is the 26 inlet/fan pulley mount. There is a washer between the eccentric mount and the pulley but that's to give it clearance for the pin that holds the eccentric mount and plate together.

I've attached a photo from each side. One I tried to line the lens up with the crank pulley and the other to show the back side of the fan pulley.

Thanks for all the help

Re: throwing my belt

Posted: Mon Apr 17, 2023 3:54 pm

by TRDxB2

Adam wrote: ↑Sun Apr 16, 2023 1:15 pm

#1) The ‘26/‘27 belt tensioner gets tensioned AWAY FROM the commutator (turn tensioner counter-clockwise while looking at the front of the car) this moves the belt AWAY FROM the commutator.

#2) If the tensioner is all the way up, then the belt is too long or stretched and requires replacement.

#3) If the top aluminum pulley has no crown in the middle, or the crown is worn off center, then the belt won’t track properly.

#4) If the bottom pulley is loose, the belt may not track properly.

#5) If either of the pulleys are painted, the paint affects tracking and pull. This is a widely known fact among antique tractor and steam engine professionals.

#6) If the fan pulley bearings or shaft are worn, the slight tilt effects tracking.

If the belt is loose do you expect it to track properly?

Re: throwing my belt

Posted: Mon Apr 17, 2023 3:55 pm

by Scott_Conger

If you loosen and pull/push your waterpump pulley "back" about 3/8" or so, I'll bet that all will be good.

Looking at the picture a second time, it looks like the waterpump pully has already walked forward 1/2" or so which further leads me to believe I'm correct on your fix. The belt is clearly crowded forward by it and is the one thing that is almost infinitely adjustable.

Re: throwing my belt

Posted: Mon Apr 17, 2023 4:12 pm

by Jerry VanOoteghem

In addition to Scott's advice, above, I'll point out that a belt that has been thrown several times and has ridden over a pulley flange, tends to be stretched out on the side that rode over the flange. Once that occurs, the un-stretched side will want to run in the center of the pulley crowns, which only acts to force the belt over the flange again, even after your initial problem has been fixed. What I'm saying is, after you fix the issue, you may find that you need a new belt. Hopefully not...

Re: throwing my belt

Posted: Mon Apr 17, 2023 4:27 pm

by speedytinc

Jerry VanOoteghem wrote: ↑Mon Apr 17, 2023 4:12 pm

In addition to Scott's advice, above, I'll point out that a belt that has been thrown several times and has ridden over a pulley flange, tends to be stretched out on the side that rode over the flange. Once that occurs, the un-stretched side will want to run in the center of the pulley crowns, which only acts to force the belt over the flange again,

even after your initial problem has been fixed. What I'm saying is, after you fix the issue, you may find that you need a new belt. Hopefully not...

You might turn the belt around after you get the alignment corrected to put the tighter belt edge more in play.

Re: throwing my belt

Posted: Mon Apr 17, 2023 8:13 pm

by Craig Leach

Hi Calvin,

It's hard to tell by the pic but there should only be the fan eccentric plate & the fan shaft cup washer there. I'm thinking the Forum has found

your problem. I agree the rotory centrifugal Dihydrogen-Monoxide circulating belt alignment pulley is to far forward. Turning the belt around is

a good idea also.

Craig.

Re: throwing my belt

Posted: Mon Apr 17, 2023 9:37 pm

by JTT3

Scott if the fan on the 2 row radiator was extended on the shaft to get closer to the radiator wouldn’t that change the alignment between the crank pulley & fan pulley? I agree now seeing the picture that the water pump pulley may be the main culprit but, and it may just be the angle of the picture, it appears the fan pulley is forward of the crank pulley.

Re: throwing my belt

Posted: Mon Apr 17, 2023 9:50 pm

by Scott_Conger

John...no, the pully lines up as original...it's just that there is an additional "snoot" on the pully (about 1.5" long) which pushes the fan "out" toward the radiator. It is all hollow and the original fan bolt works with it like it was a normal "short" one. With respect to the OP, his pulley is a ball bearing new pulley and I agree that it appears a little "forward", but given their distance apart and the fact that they both have heavy lips on them (and the fact that the waterpump pulley is crowding and deforming the belt, I suspect that any minimal fan/crank misalignment will offer negligible inputs relative to the waterpump's apparent significant misalignment

Photo credit: Ron Patterson

Re: throwing my belt

Posted: Tue Apr 18, 2023 1:55 am

by TRDxB2

Calvin what Gates belt are you using?

-

Took some pictures of my set-up with the sealed bearing pulley. The race of the bearings wasn't a tight fit so I needed to place the felt with some washers, found two that fit perfect and when bolted tight held everything in place.

--

--

--

Took some pictures with a plumb-bob to show alignment. Engine is slightly off level else the plum-bob would be right on. Not sure what washers are being refereed to in the above picture of Calvin's pulley. The shinny portion is the part of the concentric setup and what looks like the cap that goes over the felt.

--

Note the plumb-bob string is on the opposite side of the pulley and on the inside of he pulley lip. Photo makes it look different

--

--

after all this I found that my belt is too short

Re: throwing my belt

Posted: Tue Apr 18, 2023 9:24 am

by Scott_Conger

That is not at all out of alignment to the extent that it will throw a belt. The good news is that you can move it "back" if you wish, by simply shifting a washer or two to under the bolt head in front, rather than at the back. Also, you can get rid of the "cap" and the extra washer...

I run one of those pulleys on one of my Ts and recall having to do the same thing with shims...

Re: throwing my belt

Posted: Tue Apr 18, 2023 11:07 am

by JTT3

Thanks Scott for the pictures of the 26/7 fan pulley didn’t realize that it was the casting that changed the position. Learn something new every day.

Re: throwing my belt

Posted: Tue Apr 18, 2023 11:15 am

by DanTreace

chiporem wrote: ↑Mon Apr 17, 2023 3:40 pm

It is the 26 inlet/fan pulley mount. There is a washer between the eccentric mount and the pulley but that's to give it clearance for the pin that holds the eccentric mount and plate together.

Could be the issue of the new fan pulley too far forward. The new version should need only a thin washer to replace the Ford cup and felt, as the bearing is sealed, you don't need that part. Here is my install.

- IMG_1890 (620x409).jpg (46.38 KiB) Viewed 3398 times

Belt runs true on new crank pulley

Now the water pump is another issue you have, many pumps use a bolt to extend to the engine block, to help alignment, but you do need to look again at the fan pulley hub at the cylinder head and get that inline with the crank pulley.

- water pump 50 full (640x427) (600x400).jpg (134.74 KiB) Viewed 3398 times

Re: throwing my belt

Posted: Mon Apr 24, 2023 4:30 pm

by chiporem

Sorry for the slow update but life got in the way.

I did exactly as everyone suggested and it worked! Thanks for the help! As a "Newbie" to the model T it's nice to know there's a resource like this.

So here's what I did:

-Reversed the belt

- Aligned the water pump pulley with the crank pulley (there's still some misalignment between the crank and fan pulleys but she ran for ten minutes without throwing the belt)

-Adjusted the eccentric tensioner away from the commutator

and one more thing... I think I had the belt adjusted too tight originally. After everyone said to check the crowns of the two upper pulleys I started to figure out that if the belt is too tight the crowns wouldn't allow the belt to self-center.

Thanks again for the helpful and extremely fast information.

Now I'm off to diagnosing the commutator. She's running but missing!