Page 1 of 1

Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 12:00 am

by Steve Jelf

Obviously too little clearance can do it. Is there anything else?

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 2:48 am

by Allan

Not to my knowledge Steve. Others have cast doubts on the material used in replacement bushes, but I have fitted many sets of these, set to proper clearances, and have never had one seize. I believe a running clearance of .002" is recommended, but this means that clearance should be that .002" all round, meaning the bushes should be reamed .004" over the pin diameter. I am not fussed if I have .005" difference between pin and bush sizes.

Alternatively, replacing worn pins and leaving the original bushes in place will often be satisfactory. This gets around the different bush alloy specifications.

Hope this helps, Allan from down under.

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 3:56 am

by Dan Hatch

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 7:02 am

by George Mills

Steve,

Anything else?

They really need to be hyper-clean. One small particle of ream, or metal fuzz from elsewhere...and if it gets stuck and can't flush thru...while the bush is trying to lap itself in to the system constraints...will grow on itself like a bladder stone until it 'bites' into something and then really causes havoc. (My bladder stone just grew past 30mm, time for it to come out, may actually help with that old man 'gotta go' disease?)

Speaking of oil flush...I have never understood, no matter how hard I try why Ford was so particular about bush face gapping working in concert with an offset double helix internal oil groove to an absolute helix angle defined in 'minutes' to churn the lube through. (Think of an hourglass wobble as the pusher)

This combo came along about 1915 or so with the solid triple gears. The riveted gears actually had peripheral holes through the hubs for true external oiling. The conundrum comes about as where the solid gear oil groove intersects is exactly the point that would have gotten the least oil under the prior arrangement. Yeah, I know, 45 million made, worked apparently 99.9% of the time, must have been right...they just didn't leave notes why.

Listen to Dan. I've been an advocate that Ford was ball sizing from about '15 on also...I just can't prove it! I can prove that Ford was 'crush' size reaming cylinders by this time...so the technology was known. I also own the portion of the Humber Motor Car (UK) technical library that related to Ford of the era. In the one folder there is all kinds of work on ball-reaming, the trial and error to get around so-called 'push back', how to predict push back, etc. When I found that I designed a proof of concept machine that would have automatically ball reamed to size using knowledge of the era (Think pinball machine mixed with a shell loader.)...but like all things early Ford, you don't find that last piece of paper, it didn't happen

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 7:15 am

by George Mills

I'll piggy back something here rather than a new thread...

My Humber (UK) folder is really packed away, but I was able to find some e-material that I exchanged with the late Ralph Ricks when we were doing the blind push/pin tests about a decade ago.

Here is an example, of how balls reaming actually works! Were Ford to have ball reamed, it also may explain a bunch. Somewhere I do have proof that Ford did heat treat Z. (Heat treat yellow metal anneals it rather than hardens it). I recall being really curious about the hold temperature as it was within 10 degrees of precipitating one of the elements but just not quite there, a very curious point, yes? Look at the ball ream life cycle...it adds back IN compressive stresses to the surface....hmmmmm

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 9:55 am

by Scott_Conger

Ford Service Bulletin shows how to make a series of progressive larger tapered burnishing tools to size triple gear bushings and encouraged FORD agents to thusly treat all bushing replacements in this manner. Drawings with dimensions was supplied and FORD recommended that the burnishers be made from an old axle or a good tool steel.

The final bore diameter of the bushing would be somewhere shy of .682 as that was the finish size of the burnishing tool and there will be some spring-back in the bronze material. Additionally, the bore of the bushing would have a layer of very densely compacted material, a feature which is lacking in today's repair(s) along with the bushing being tightly swelled into the gear.

For Info: Factory drawings show ground pins to be .6775 at maximum material condition

Assuming a burnished bushing finishes at nominal .6815 and ground pin at maximum size of.6775, one would expect a total clearance, as repaired, of 0.004" or .0045 if the pin was at minimum diameter

I personally do not need further documentation or opinion as to what the "correct" clearance should be (for my personal work) as FORD documented all of it and I doubt that they were swamped with come-backs for spun bushings

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 10:01 am

by Steve Jelf

Now I'm getting in over my head. I've never studied ball reaming. Can somebody describe/explain it or direct me to a source (preferably illustrated) that does? Google is not being helpful on this one.

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 10:16 am

by TXGOAT2

I believe it amounts to a mechanical hardening and sizing procedure.

Neither reaming nor honing will give the same result.

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 10:27 am

by Scott_Conger

Steve Jelf

...you're searching the wrong term...try "ball sizing"

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 11:45 am

by Art M

In the past, I never believed that too little clearance causes seizer until I thought about the pin wear. This causes the hydrodynamic lubrication to go out the window.

The bottom line is: it's more important to understand that at least .002 inch clearance is needed than it is to understand the theory behind it.

Art Mirtes

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 12:34 pm

by Steve Jelf

...you're searching the wrong term...try "ball sizing"

Yes, that got me on the right track. Thanks!

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 12:51 pm

by speedytinc

I agree with the extra clearance theory. I have been giving .004-.005" clearance. I do a fine lathe bore. No reamer. My theory is that a reamer makes like a coarse thread That gets knocked down with break in.(if the bushing doesnt seize first.) Boring to the listed outer clearance range works in that the finish bore stays that machined size. No break in worries. I have had no issues from this method. (even with customers who are not mindful of breaking in procedures with new motors) I do use Z bronze bushings.

I am not opposed to ball sizing, I just dont have the capability currently.

I have also come around to the idea of resizing original bushings to re-use. (thanks forum members)

You cant beat the original bushing material.

To answer you question about "extra" things to do. The bushing flange has to be machined down to get proper gear height position. .010" I believe.

After cutting that flange down, one must re chamfer the sharp inner edge to direct oil into the oil gruves. I give extra chamfer & insure the gruve has no obstruction. I will widen the gruve entry point. Maximize possible pin/bushing lubrication.

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 1:23 pm

by speedytinc

One thought on ball sizing.

I notice that as I bore new bushings, there is typically a side that doesnt get cut in the first pass. Bushing is not centered to the gear OD. Weather that be by an off center gear hole or in the bushing.

I would think a clean up cut in the bushing would be required to center the hole before ball sizing.

Re: eized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 1:52 pm

by Art M

It appears that it is simplest to change the pins. Change the bushing only if necessary. I suspect that in most cases, the bushings can be reused.

Art Mirtes

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 2:12 pm

by Jerry VanOoteghem

speedytinc wrote: ↑Sat Jun 24, 2023 1:23 pm

One thought on ball sizing.

I notice that as I bore new bushings, there is typically a side that doesnt get cut in the first pass. Bushing is not centered to the gear OD. Weather that be by an off center gear hole or in the bushing.

I would think a clean up cut in the bushing would be required to center the hole before ball sizing.

It is not nearly as important for the ID & OD to be concentric as it is for the ID & PD, (Pitch Diameter), to be concentric. The OD of the gear plays no real role in its function, whereas the location of the pitch diameter is critical in determining the runout of the gear teeth. Ideally, you would expect the OD & PD to be concentric, but that's not always the case. If I found runout in the OD, it would immediately make me question what the PD runout is. In any case, runout in the PD is the most important measurement.

Not to detract too far from the point you were trying to make, achieving perfect concentricity prior to ball sizing is very important.

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 5:42 pm

by DanTreace

On the broaching subject, this is an interesting tool published by Murray Fahnestock in article with Ford Owner Dealer.

Gives note of the clearance for the .002" running fit, to make the broach .004" larger than the triple gear shaft.

Re: Seized triple gear bushing: Why?

Posted: Sat Jun 24, 2023 5:49 pm

by Dan Hatch

I tried the pins years ago when Dan T and I talked about burnishing. Than I from Precision Balls. Com. Here is link to my original post.

http://www.mtfca.com/discus/messages/82 ... 1524277396

Email me if you have questions about burnishing. Dan

Re: Seized triple gear bushing: Why?

Posted: Sun Jun 25, 2023 11:11 pm

by Dan McEachern

There is a solution that never fails................

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 1:48 am

by Liberty Garage

I was the first to use Dans needle bearing triple gears in my overhead powered speedster. Over 25 years and no problems Im sold!!!

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 2:40 am

by Erik Barrett

Transmission bushings never fail from being too loose, only from being set up too tight. Same goes with boring piston to cylinder wall clearance too tight. People think setting them tight will lead to longer life when in fact the opposite is true. We have seen this many times and had to deal with the aftermath.

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 3:38 am

by Dan Hatch

One more thing not touched on here is the pin itself. Have not seen an original pin that was not egg shaped from wear. The replacement pins are not ready to use out of the box. The finish on the surface that bushings run are not smooth enough, this will wear the bushing or cause it to bind. You have to spend the time to polish them if you use those pins. Also they do not have the shoulder on the backside to prevent the pin from coming through the flywheel. I only know of one person that makes them correct.

Also, the bushings themselves should be the expensive ones. Not the cheap ones.

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 9:22 am

by Steve Jelf

I only know of one person that makes them correct.

And that person is ...?

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 11:10 am

by Scott_Conger

Dan

I don't dispute that Murray did this piece that you posted, but do the math!!

the result is a hole which is .6905 which is wildly oversize

somewhere between Murray's notes and the publisher's ink, something went badly awry!

Even FORD documents (not drawings) have minor errors creep into publication, but I'll stick with what they published in the service bulletin that I posted above. It clears up the dimensional controversy and results in foolproof parts (but boy, do Dan McE's gears look nice! They may well be my next ones)

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 11:35 am

by George Mills

Yes, that 6905 (11/16" + 003) dimension is quite gross. the factory spec after finishing was .6785-.6790. Yes, 4 digits accuracy and I do believe Ford was was able to hold to about 1/2 that range.

There would of course been a spring back factor from the mandrel if mandrel swedged, but at best probably something at the 4th decimal place? I just don't know. That STILL leaves way too much.

Then again, I'll share. When Ralphie and I did the blind bushed pin test we found some bushes out to 008 oversize and reportedly they came from a car that was known to cruise I5 at freeway speeds...not condoning the practice, just saying how tolerable some instances have been when Ford themselves recommended 005 before rebuild? (and for all you guys who have determined what old clearance really means...does that translate to a real 010" actual? Just asking, not being nasty, and always curious)

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 11:49 am

by Scott_Conger

George

First I have the greatest respect for your background and metallurgical knowledge. I've seen the .679 value for installed bushings...and that would leave .0015 clearance on a new pin (pin at max condition). I'm pretty certain that this is actually the raw value expected after pressing the bushing into the gear, or as received from FORD as an assembly, pre-installation.

Edit for readers: George Mills has kindly supplied a drawing which shows the .6785-.6790 value to be installed bushing/gear subassembly as reamed in place (not a raw pressed bushing as I earlier typed).

I think the important thing about that value is what follows in the documentation and it states that they are then reamed to size. Later, FORD determined that a broached finish was advantageous for dealers and we are blessed with the drawing which unequivocally defines what a finished diameter on an assembly would result (less spring back which will fall into the .000x range). If you will refer back to my earlier posting or see below, you'll see that the .679 bushing that you're referring to will be sized to .680 by the first broach and then increasingly larger sizes until .682 nominal is achieved. POOF! .682 (hole) - .6775 (pin) = .0045 (or so, clearance). Now, how about that! This falls exactly in the middle of "allowable range" of .004-.005 (see below). This aligns well with standards of the 1920's which absolutely define a .002" Running Fit to be a

range of actual total clearance depending on load...and coincidentally for the pin diameter and load, .004 is defined as a .002" Running Fit. For young machinists that will argue that .002 Running Fit equals .002 total clearance, I will direct you to close your CNC manual and research early 20th Century practices and standard definitions - they are not what you work to. BTW George, I know you know this, but there are many or most who do not.

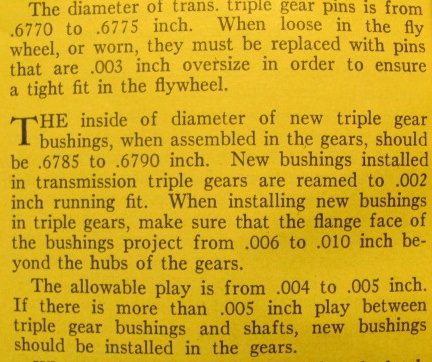

- burnish triple gear pins4.jpg (89.16 KiB) Viewed 3770 times

Re: Seized triple gear bushing: Why?

Posted: Mon Jun 26, 2023 12:01 pm

by Dan Hatch

Re: Seized triple gear bushing: Why?

Posted: Tue Jun 27, 2023 10:31 am

by Original Smith

The Ford Service book states a .002" running fit. I've never been sure of what that term means? I saw it used twice in the above posts.

Re: Seized triple gear bushing: Why?

Posted: Tue Jun 27, 2023 10:51 am

by Scott_Conger

"Running Fit" is a class of tolerance

Running or Sliding Fit can encompass any one of 9 sub-classes of fit from RC1 (Close Sliding Fit) all the way to RC9 (Loose Running Fit). FORD's ".002" Running Fit was likely an early equivalent to RC7 Free Running Fit or RC8 Loose Running Fit

Using the below calculator and entering ".677" for "nominal", "RC" for Running or Sliding Fit, and then either RC7 or RC8 and by going down to the "FIT" section, you will suddenly see that your final clearances are on a much looser side than you would imagine. Given that FORD's smooth broaches gave a nominal .004 clearance, and .005" clearance was at max limit, I'd imagine that FORD's class of fit would be defined today, by ANSI B4.1, as the upper limit of a RC7 Free Running Fit that is defined as ".0045" at it's upper limit.

FORD's ".002" was never a tolerance or final clearance fit - it was part of defining what class the "Running Fit" was.

https://amesweb.info/fits-tolerances/an ... lator.aspx

Re: Seized triple gear bushing: Why?

Posted: Tue Jun 27, 2023 11:26 am

by Craig Leach

I heard once that one should never use grease as a assembly lube as it will prevent the oil from getting into the bushings? Anyone ever hear that?

Craig.

Re: Seized triple gear bushing: Why?

Posted: Tue Jun 27, 2023 11:44 am

by speedytinc

Craig Leach wrote: ↑Tue Jun 27, 2023 11:26 am

I heard once that one should never use grease as a assembly lube as it will prevent the oil from getting into the bushings? Anyone ever hear that?

Craig.

Yes. & it makes sense. If you plug the oil access cut, countersunk base & the gap between the bushing & flywheel, Oil might not wash out the assembly grease before the bushing seizes.

Re: Seized triple gear bushing: Why?

Posted: Tue Jun 27, 2023 12:59 pm

by RajoRacer

I agree with John here - assembly lube is for a pressurized system, I believe.