Page 1 of 1

1918 Roadster Seat Wood & Mounting

Posted: Thu Dec 26, 2024 2:56 pm

by JR Ewing

I have a 1918 Roadster that I’m trying to get back together. I have new seat springs for it but the car is missing the wood that supports the seat back. Can anybody help provide me with the info I need to build the seat back wood support and details on how the seat back mounts to the body and/or wood support. Also, does the seat back just sit directly on the metal cover over the gas tank or is there wood or other material between them?

Thanks for the help.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Fri Dec 27, 2024 9:36 am

by John kuehn

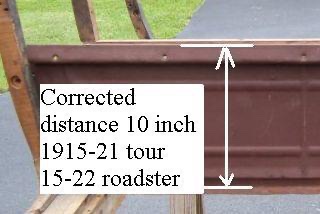

This may give you an idea how the wood back fit. Others may have some ideas.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Fri Dec 27, 2024 10:39 am

by JR Ewing

I did find that and browsed thru other pictures, but it’s all pretty vague. Thanks for the reply.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Dec 29, 2024 11:29 am

by DanTreace

This is a 1915 runabout body wood, may be of some help. The seat cushion should rest on body wood of the seat, the metal hinged cover is slightly below the seat wood. In this 1915 body the tank cover is hinged wood. Last photo is an uncovered backrest of a 1922.

- 1915 rear view.jpg (96.75 KiB) Viewed 40128 times

- 8184.jpg (26.45 KiB) Viewed 40128 times

Inside View of a 1922 runabout, showing some of the wood frame of the seat back rest for that year.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Dec 29, 2024 2:38 pm

by John kuehn

I have a 1919 Roadster and when I rewooded it and it came to the back rest mounting some people have moved the spring up some to avoid the top vacant area above it. You can see that in one of Dans photos. I’m not sure that all were done the same way because of up to 5 body builders who Ford used during the 17-22 time period. You need to remember to add extra padding above the top of the spring if it stays all the way down on the seat frame.

Which ever way it’s done and it looks OK that’s the way to do it.

I wish Model T’s were all the same in the way they were put together in the year range but they weren’t as I found out with the 1919 Roadster and the 1921 Touring I restored.

In general they were the same but the details weren’t.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Dec 29, 2024 6:45 pm

by JR Ewing

Thanks, this helps. The snyders seat back I have extends up to, if not past the tack strip on the body. I’m just not sure how high, and how it’s supposed to mount. My gas tank cover is a hinged metal lid. Should this be bordered with wood for the seat base to sit upon and do these same pieces of wood act as the tack strip for the bottom of the seat backs upholstery. I have a NORS seat upholstery kit. I’ve already recovered the seat base and it fit well. Just trying to figure out how and where to mount the seat back and I can start on that. I just want to make sure I get the seat back in the correct place. Otherwise the upholstery is going to be off.

Thanks for the help.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Mon Dec 30, 2024 12:19 am

by Duey_C

The July '17 (originalish) body on what I call an '18 here has a handy "shelf" for the back spring cushion bolted to the body, it fits right in yet I've found no evidence of anything above that other than the upper tack rail.

Granted, I do not know who built the body. The car was close around the Milwaukee area until the early-mid 70's so the body may be way different from yours.

p.s. Ignore the paint put on in the late 70's and the starter switch which I was messing around with in 2016 with a pre-existing hole ('23 engine).

I'm likely wrong and this will not help...

Re: 1918 Roadster Seat Wood & Mounting

Posted: Tue Dec 31, 2024 12:12 pm

by JR Ewing

Those pictures are very helpful. Thanks. Can anybody tell me or show me how the seat back mounts and how high it is supposed to mount?

Thank you!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Tue Dec 31, 2024 1:55 pm

by DanTreace

JR Ewing wrote: ↑Tue Dec 31, 2024 12:12 pm

Those pictures are very helpful. Thanks. Can anybody tell me or show me how the seat back mounts and how high it is supposed to mount?

Thank you!

Several ways, some 1916 up used metal clips tacked to wood upper tack strip, some had lower metal channel to fit the backrest spring.

Later just used strips of excess trim, like top material, looped, and tacked to wood upper strip.

Usually fit the covered seat cushion first to determine lowest position of the backrest spring, otherwise removing the seat cushion is hindered.

Using fabric strips aids in getting the hanging spot right and level, and be sure to add enough padding to the top of the spring for smooth fit of backrest upholstery without a cavity under.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Wed Jan 01, 2025 8:11 pm

by JR Ewing

Thanks. Does anyone know where I can find more information on what this seat box area should look like? See pictures.

It looks like repairs have been made. The drivers side is 90 degrees and the passenger side is not. I would think it’s symmetrical but I’m not sure. Any help and/or pictures would be great.

Also, is there any good reference info on how these bodies were put together, especially the wood structure. Mine is a 1918 Roadster.

Thanks!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Wed Jan 01, 2025 9:09 pm

by John kuehn

I’m assuming you’ve recovered the seat spring. If you have let that be your guide on how the seat will sit in the seat frame. I don’t know if you’re buying a kit for the wood or have already done that. There are 2 wood kits suppliers. Maybe you’re going to make the wood yourself.

Whichever one you buy from be prepared that the wood kits don’t always “ drop in” when you fit it to the body itself. There will probably be a little whittling when you do it.

As far as that sheet metal frame goes, Ford didn’t do a great job when he had the bodies built but the frame did its job and your isn’t the first that had to be repaired. After all Ford wasn’t building a precise Rolls Royce for us Model T hobbiest to go by!!

The one in my 21 Touring was about toast and I reparied it so the upholstered seat spring bottom fit just a little loose but not much. It worked well for me.

Others will comment about it and maybe will post pictures or their experience.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 9:10 am

by Wayne Sheldon

The biggest problem with the runabout seats from 1914 through 1922 is that there were several major variations in how they were made. Variations varied from one body builder to the next as well as tending toward differing years or ordering runs. However, the different methods and styles came and went then came again. As far as I know, all three of the common variations did have the major seat support riser was wood, one piece on each end of the gasoline tank attached to the main body sills. The height of those wooden risers varied slightly depending upon which variant of the seat frame that car had originally.

There were at least three major variations of the seat frame. One, except for the steel "heel kick panel" is almost entirely wood for the seat framework. Another, the basically entire sett frame itself is all steel. The surprising thing is that this all steel seat frame apparently was used during part of 1915. Much of 1915 however had wooden seat framework. That steel seat frame seemed to largely disappear before 1917, only to return again around 1920. Past discussions on this subject have failed to come to a definitive conclusion, however a few researchers have speculated that the seat frame was a large chunk of steel easily replaced by wood and eliminated in a minor cutback for the war effort.

The steel seat frame was a bit cheaper to stamp out in large numbers than having several men hand make wooden frames. So after the end of the war, Ford seems to have gone back to the steel frame.

The third major variant had a bit more steel attached to the kick panel with a small amount of steel mixed in with wood. So it was sort of a mix of the nearly all steel seat frame and the nearly all wood seat frame.

The wood that somewhat supports the seat back springs is quite different in how it is made and how it attaches to the seat base, depending on which variation the seat base is.

My 1915 runabout was missing nearly all the seat back wood. And the wood plans I had picked up years earlier for a few bucks at a swap meet? Didn't have anything about the upper body rear tub woodwork. Between the incomplete plans and what original wood remained in the body, I was able to recreate most of the body wood just fine. The seat back? All I could do at the time was take a wild guess and cobble something together to do the job. You may need to do the same thing.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 11:54 am

by DanTreace

JR Ewing wrote: ↑Wed Jan 01, 2025 8:11 pm

Thanks. Does anyone know where I can find more information on what this seat box area should look like? See pictures.

It looks like repairs have been made. The drivers side is 90 degrees and the passenger side is not. I would think it’s symmetrical but I’m not sure. Any help and/or pictures would be great.

Your metal framing does show Pop Rivets, so that frame was reworked by former owner.

This link could help, it shows some nice photos, if you scroll down to Dec. 21, 2012 of a 1920 Beaudette bodied touring front seat. A metal framed seat base runabout would be very similar to this front seat of the same mfg. Many seat bases were made mostly of wood.

https://www.mtfca.com/discus/messages/2 ... 1356213511

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 12:39 pm

by Dan Hatch

Find a copy of Millers or Parker’s wood plans.

Some of you younger guys should find out what happened to the master plans those guys made and buy them.

You could get yourself into the Wood body plans business.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 12:44 pm

by JR Ewing

Thanks for the replies.

The more I dig into this roadster body, the more I realize how off some things are. At some point somebody attempted to re-wood this body themselves. Some of it looks ok but other areas should be done. I fear I might get carried away and re-wood the entire thing but I’ll do my best to avoid that if possible.

Are there any books or wood plans for re-wooding a body available for purchase? Or, any place I can find good pictures of the wood framing for a 1918 roadster or similar years? I do have plenty of experience and even have a cnc router which can help with some of the pieces, but it would be nice if I had either patterns or good photos to go off of. More to save myself time since I still work full time and then some.

I will revisit the seat area once the wood structure is restored.

Thanks!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 12:49 pm

by JR Ewing

DanTreace wrote: ↑Thu Jan 02, 2025 11:54 am

JR Ewing wrote: ↑Wed Jan 01, 2025 8:11 pm

Thanks. Does anyone know where I can find more information on what this seat box area should look like? See pictures.

It looks like repairs have been made. The drivers side is 90 degrees and the passenger side is not. I would think it’s symmetrical but I’m not sure. Any help and/or pictures would be great.

Your metal framing does show Pop Rivets, so that frame was reworked by former owner.

This link could help, it shows some nice photos, if you scroll down to Dec. 21, 2012 of a 1920 Beaudette bodied touring front seat. A metal framed seat base runabout would be very similar to this front seat of the same mfg. Many seat bases were made mostly of wood.

https://www.mtfca.com/discus/messages/2 ... 1356213511

Yeah, I don’t think these corners are original. I would hope not anyways.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 1:28 pm

by Dan Hatch

Here is a link to a thread about wood plans.

viewtopic.php?t=8472

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 02, 2025 1:45 pm

by John kuehn

JR

Go to cimorrelli.com to access Model T ford digital library. Follow the links to wood plans. There are partial plans by Mel Miller that can help. Not all but some to maybe go by. Door wood plans seem to be complete.

Also classicwoodproductsllc.com sells the wood kits for Model T’s if you decide to buy a kit.

Leon Parker drew up plans for Model T Tourings and Roadsters and used steps from Mel Millers plans.

When Leon Parker passed away all his plans were sold and since disappeared. And that’s a shame! This was a hot topic for a while as to what became of them. Whoever bought them is sitting on them for some odd reason.

Having them avaliable can only be positive for the hobby.

I still don’t understand why the MTFCA couldnt aquire them for use. The club ought to pursue where they went.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Fri Jan 03, 2025 12:20 pm

by TRDxB2

As mentioned above - Here is the link to the wood plans

https://www.cimorelli.com/mtdl/woodplans/default.htm

--

--

--

You can zoom in on the displayed page and scroll left/right & up/down to see it better

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 1:07 pm

by JR Ewing

I’ve been through that website many times. I wish there was more info pertaining to roadsters, but some info seems to apply. If I had to replace all the wood, I’d most likely buy a kit, unless the plans were available. I would like to build as much of the wood I need to replace as possible. It’s just hard to determine what’s right and what needs replaced since finding good info and/or pictures has been difficult. The info and help I am receiving here is a huge help and is giving me some ideas on how things should be. I did find that the body was off due to the wood so I have more to address than originally thought. If anyone has plans, I would be more than happy to purchase a copy or even rent them, if that’s a thing.

Thanks again for all the help. I’d be lost without it!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 4:37 pm

by rickd

Joshua, I have a copy of this article by RV Anderson about re-wooding the 23 low cowl roadster. Pretty detailed instructions. If you can't find it online and want a copy email me. Like most of my document collection this is pre-digital.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 5:11 pm

by JR Ewing

Thanks Rick. Email sent. From what I can see, it appears to be a helpful article. I appreciate you sharing this. I did not come across it online.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 5:15 pm

by JR Ewing

Another area I am having trouble with finding good reference pictures or documentation is the factory body seams where the cowl, sills and rear quarter panel all converge. Because the previous owner got his hands on it, I am unsure if there were one or two seams in this area, where they were located and if they were leaded smooth or filled using another method. Are the seams located in the same location on the left and right side of the body. Obviously might be a little different since the drivers side does not have a door.

Anything helps and is appreciated.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 6:42 pm

by John kuehn

Are you talking about the beads? If I remember the seams or beads overlap each other and they could have been spot welded. I do know that on the back panel of my 21 Touring they overlap and originally they were spot welded together. When I replaced the back panel I carefully drilled the area where it was spot welded and then replaced it with a new one, spot brazed it back together very carefully using low heat.

Others may know more that can help.

Also some pictures of the body where your talking about would help.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 8:12 pm

by JR Ewing

I’m referring to the seams that would be between the rear side body panel and what is typically referred to on later model cars as rocker panels. I’m thinking there is a seam at the front between the “rocker panel” and the bottom of the cowl sides as well. I’ve attached pictures. The drivers side seams are visible. Not sure if this looks correct or not. I’m also wondering if these seams were leaded smooth or if the seams were left visible.

Thank you!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 8:49 pm

by John kuehn

JR. I’m pretty sure that the seam is left visible. The one on the passenger side (door) looks like it was leaded over or maybe bondo. Originally those seams were spot welded. The seam fit flat. The remains I’ve seen of partial bodies those seams were spot welded. Some have been riveted with small steel rivets and hammered pretty flat so it’s not real noticeable over the years for a repair. To do that you can use a bucking bar on the inside and use a small flat hammer on the outside.

But I think this was done with the body panel off and not on the car.

When looking at a nice unrestored body you can see small imperfections if you look close enough. Paint runs also by the way!

If you use sandpaper over the joint on the drivers side you’ll probably see the small spot welds. If you see them that shows it was spot welded.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sat Jan 04, 2025 11:21 pm

by JR Ewing

I’ll have to start stripping those seam areas and see how they are joined and if they are intact as original. I have no doubt that they were mudded over by the previous owner when he last worked on it in the 80s. There are several crude repairs with either fiberglass or just mudding over rusty areas. Like all projects, this one too is snowballing.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Jan 05, 2025 6:53 am

by rickd

Looks like both sides have had previous repairs. The driver side fake door panel looks to be replaced all the way to the top edge. The passenger side "rocker" panel area as well. Both sides have unfinished seams probably because of the difficulty of welding the seam in those areas due to the sheet metal is laying directly on top of the sill wood. Pretty sure those open seam areas on both sides should be smooth.

The vendors used to sell repair panels for those areas, if you can't find repair panels find someone that can help you fabricate and weld in new sections. Pics attached are a later touring but it kind of shows the "rocker" areas and what those lower areas look like. Good luck, you have some work to do.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Jan 05, 2025 1:05 pm

by JR Ewing

Thanks for the photos, Rick. Fortunately, I have a lot of metalshaping and coachbuilding experience and all the tools and equipment to perform the tasks required. I am just not familiar with Model Ts. I do see that the fake door has an overlapped seam at the rear edge of the bead. From your comment, I am assuming this is not correct. This is the information I am struggling to find. I have found it nearly impossible to find any reference pictures or other info that shows or describes where and how the factory seams were originally and since this body has had previous "repairs", I cannot use it to accurately determine what is correct and what is not. Maybe I am not looking in the right places, but this forum has been a great resource for solving these types of mysteries. Thank you to those that have helped answer some of my questions, and I apologize that I keep finding more questions the more I dig into this car.

I am surprised at the lack of sheetmetal repair panels for the earlier Model Ts. I figured there would be at least one company making patch panels for these cars, but I have not come across any making them today. They all seem to cater to the later years.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Jan 05, 2025 9:39 pm

by Hap_Tucker

JR,

Welcome to the affliction. Lot's of good advice above. Model T’s can be a great fun puzzle. From what you have shared so far, It sounds like the car had a “fix-up” sometime in the 1980 or so. And before that an unknown history. Because the Model T parts can interchange so easily – it is usually good to confirm what year range you have for the body, engine, other chassis parts etc.

Note one of your photos shows the inside of the front driver’s compartment and it appears to have a starter switch. If that is original to the car – it would appear the car was 1919 or later. Of course that part could have been added later.

Have you had someone knowledgeable about the Model Ts confirm your 1918 dating? And the 1915-early 1922 roadster bodies were very similar. (The USA touring cars changed a little earlier than the roadsters).

I’ve included some general information that may be of some help below:

+++++++++++++++++++++++

Original posting was: Turtle Decks. Do they all have 2 latches? At:

http://www.mtfca.com/discus/messages/50 ... 1451743057 but that link no longer works. Summary is below:

By John T. Tannehill III, Hot Coffee, MS on Friday, January 01, 2016 - 08:02 pm:

Chris short answer is no the 23-25 turtle deck as well as the 26/7 roadster turtle decks did not have handles. I know that 13-22 roadster turtle decks all had two handles though the shape of the handles changed

By Mike Walker, NW AR on Saturday, January 02, 2016 - 08:57 am:

From earlier discussions here, the consensus is that the flat handles first occurred at the same time as the notch for the access, which was for the '19 model year.

+++++++++++++++++++

See the link: Model T Ford Forum: Question about a 23 touring body??

It discusses how parts and be mixed and matched but they aren’t quite right. In this case a 1915-1920 (I believe they continued into 21) ish touring front with a later 1922ish – 1925 rear seat section.

++++++++++++++++++++

Note at : Model T Ford Forum: 1912 Hayes bodied resto still worked Jan 5, 2025:

An Aug 8, 1997 comment by Trent was reposted by me (Hap): Six open car body makers:

Between 1915 and 1921 the Ford Motor Company used touring car bodies supplied from six different sources. These were 1) the Fisher Body Company, 2) the O.J. Beaudette Co. of Pontiac, MI, 3) The Kelsey Co., 4) the Wison Body Company of Detroit, 5) The Kahler Manufacturing Company, and 6) the Ford Motor Company. The bodies produced by these companies vary somewhat in the details. For example, some used wooden gas tank covers under the front seat while others used steel. Both types were used at the same time. Some used pressed steel floorboard risers, others used risers made of wood. Again, both types were used at the same time. Some used a cowl assembly made up of two pieces riveted together, others used one that was a one piece stamping.

The same type of comment can probably be made about the bolts that you refer to. Early production of 1915 touring bodies by some manufacturers used wood for the front seat framing while others used steel. The later type used the bolt through the side to tie the two halves of the body together. Bodies using the wood framing apparently did not use this bolt.

As time went on, more of the outside suppliers adopted the steel front seat framing, and consequently, more used the carriage bolt on the sides. The exact date of complete change over is not known at this time, but it is generally accepted that it had occurred by January 1916.

Regards,

Trent Boggess

(reposted by Hap Dec 21 2002)

)And again Jan 5, 2025)

++++++++++++++++++++

https://www.modeltford.com/item/9490.aspx Turtle deck beaded patch, for edge under lid 1915-22

+++++++++++++++++++

Howell’s Sheet metal – a long time ago good panels and patch panels. Posting at:

viewtopic.php?t=45778

Indicates it could be a long wait in some cases.

+++++++++++++++

Very Respectfully,

Hap l9l5 cut off

No clue why an extra illustration shows up -- but I'm done for the night.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Sun Jan 05, 2025 10:29 pm

by JR Ewing

Thanks Hap, for the info. Everything I have checked indicates that the car is 1918. Yes, the electric starter was added. Engine number indicates it’s a 1918. I’m not sure how to date a body. I have not see any markings to date it nor would I know the subtle differences between the years to date it. This afternoon I disassembled the body and broke down the panels. The wood needs help, I’ll most likely just replace it all, and the sheet metal requires many repairs. I really didn’t need to turn this thing into a big project, but I’m glad I did. I’m in no hurry and it’s for the best. Add is a picture of the car after I purchased it and got it running and driving. I am not planning to keep the turtle deck. I bought it with the intention of making it a pickup and will most likely build a bed for it.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Mon Jan 06, 2025 11:32 am

by JR Ewing

I am curious about the seam on the drivers side body panel. There obviously needs to be a vertical seam somewhere on this panel since the entire panel was not formed in one piece. My roadster body has an overlapped seam running vertically just at the rear bead edge of the fake door. I was not sure if this was correct, but I ran across another post showing good photos of their roadster body with the seams exactly the same. I am now thinking this is correct. If one were to place a lapped seam in the middle of the panel and wanted it to be discreet, this would be the place to do it. Can anybody confirm this for me? I am still wondering if all the seams were left visible or if they were filled with lead or some other method.

Thanks!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Mon Jan 06, 2025 5:11 pm

by John kuehn

That’s the way Ford did it and that would be good enough for me.

JR I don’t know if you’ve ever had a Model T engine apart but when you start cleaning up the engine and cleaning up the engine pan it really will make your head spin as it has many others who begin to work on a T.

The pan ears and the front piece under the crank shaft are soldered in and in other words it’s a slop job of soldering! No kidding!

Ford was in high production to build his T’s and it was done in a fairly fast and steady way. The T was a really good car for its time.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Tue Jan 07, 2025 3:53 pm

by JR Ewing

Yep, good enough for me too. I just wanted to confirm that this was correct and I have thanks to help from the fine folks on this forum. I have also tracked down some wood plans for this roadster and looking forward to having them in hand. I bought this car with no intention to restore it, but I’m glad I decided to take the plunge. I think we all know far too well how these things snowball and I’m looking forward to making some progress. I’m sure I will have some more questions as I progress. Thank you to all of you that have provided me with help. It is very much appreciated!

Re: 1918 Roadster Seat Wood & Mounting

Posted: Wed Jan 08, 2025 4:31 pm

by Harley_97

JR, I am also in need of wood plans for my 17 project. On my 17-22 body panels you can clearly see the spot weld as have been talked about above. My drivers side panel was spot welded in 13 spots, 4 places on the passenger side blow the door. I'm thinking that these panels were most likely spot welded before being attached to the body wood, perhaps in a fixture. It's also interesting that the fasteners that attach the rear panel and the side panel did not have any filler covering the heads, just ground flush.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Wed Jan 08, 2025 4:32 pm

by Harley_97

More pictures.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Wed Jan 08, 2025 4:42 pm

by Harley_97

One more picture.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 12:57 am

by JR Ewing

Thanks for the pictures. Can never have too many reference pictures. So the screws that insert through the trim and hold the rear panels to the center panel were smooth, no slot?

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 5:37 am

by Wayne Sheldon

Details on the 1915 through 1922 open bodies varied greatly depending on which of the six or more companies built the body originally, the year or batch runs ordered, as well as alterations in the hundred years since.

When I was putting my 1915 runabout together, I wanted to get it as right as I could. To that end, I consulted numerous people that had restored similar cars, and looked at the remnants of quite a number of car's sheet metal. One year, at a Bakersfield swap meet, I stumbled into a similar discussion about the late 1910s runabouts, and their differences. Ended up with about five of us walking around the swap meet for almost two hours looking at as much sheet metal as we could find there. It just so happened that there was a lot there that year. Had I wanted to, and if I hadn't already gotten my runabout body, I could probably have assembled four or five runabouts from that one swap meet! One seller had most of about three runabout bodies at his one space. The bunch of us spent probably twenty minutes there comparing the differences between just his body panels.

It was over ten years ago, and I am beginning to forget some of what we surmised.

I sure would like to see a definitive article on the detail changes and timelines through those models and years. Otherwise most of what I have is guesswork.

Part of the issue, and an important part of the history, is that the introduction of the new 1915 style open cars was delayed for several months due to problems with production. The main problem with the production was that the addition of the deeper attached cowl at the front of the body did not want to cooperate with the sheet metal stamping. Instead of forming as desired, panels were buckling badly and ruined in the process. Apparently, part of the early "fix" was to cut buckled panels salvaging good front or back areas and splicing them together with spot welds. The exact cut and fit of splices varied depending on available good sections. At that swap meet, we looked at runabout side panels that were not spliced, but full size good stampings. And the spliced panels we saw varied in where and how they were spliced.

I would really like to find out? Maybe someone knows? How many years were the spliced panels used? Opinions in past discussions vary from spliced panels being used only two to three years all the way to a firm belief that spliced panels were common well into the mid 1920s. The fact is, I do not have the answer to that one. But I know I have seen them both spliced and single panel. Henry of course would have wanted to make the single stamping work as quickly as possible as it required much less hand work to assemble the body and therefore saved a lot of money in the long run.

On mine, the splice was made very neatly along the bead forming the fake door on the side panel. It was neatly cut, and sits together snugly in such a way that unless you looked very closely, you would never notice the cut edge. Down near the bottom corner of the fake door, the cut angles back a bit, then goes straight down to under the body edge. No attempt was made to fill or hide that area of the seam.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 10:24 am

by Harley_97

Yes JR, that is correct. The head of the machine screw does not have a slot. I'm not sure of the correct name for the body iron that creates the bead down the back of the body is, but the holes in that part are counter sunk to match the head of the machine screw, 10-24 thread. The driver's side panel fit is as Wayne has described above, the notch and the splice were made very neatly along the bead forming the fake door.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 10:27 am

by Harley_97

Close up pictures of the rear body molding machine screw.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 10:48 am

by John kuehn

When restoring my 1919 Roadster I was missing one side of the trim piece or body iron. I ordered the correct size from McMaster Carr. It was listed under molding and trim in their catalog. That was years ago.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 11:02 am

by Jerry VanOoteghem

JR Ewing wrote: ↑Thu Jan 09, 2025 12:57 am

Thanks for the pictures. Can never have too many reference pictures. So the screws that insert through the trim and hold the rear panels to the center panel were smooth, no slot?

I wouldn't be so sure that they didn't have slots, at least to begin with. It's possible that un-slotted screws were used, but also likely that they had slots in them, before being ground flush with the trim piece. (I believe the term for this flush grind is "frenching in.") One of the screws shown, may just barely be showing the last trace of a groove.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 12:03 pm

by JR Ewing

Jerry VanOoteghem wrote: ↑Thu Jan 09, 2025 11:02 am

JR Ewing wrote: ↑Thu Jan 09, 2025 12:57 am

Thanks for the pictures. Can never have too many reference pictures. So the screws that insert through the trim and hold the rear panels to the center panel were smooth, no slot?

I wouldn't be so sure that they didn't have slots, at least to begin with. It's possible that un-slotted screws were used, but also likely that they had slots in them, before being ground flush with the trim piece. (I believe the term for this flush grind is "frenching in.") One of the screws shown, may just barely be showing the last trace of a groove.

Correct... I was merely referring to the finished appearance and whether or not smooth fasteners are correct. I have seen some pictures of the same profile trim on the rear deck of the roadsters, below the turtle deck, that had obvious fasteners (most likely wood screws as I believe they screw into the wood) but the screws were flush with trim and no slots. This can only be a result of dressing the screw heads after installation. I am assuming this is the case with the trim attaching the roadsters side and rear body panels. Mine had slots but the body I have had been previously disassembled and reassembled prior to my ownership. I am sure this is a common. So what do people do when restoring one of these, assuming they separate the panels? Do they use slotted screws and call it good, or are taller counter sunk screws available that allows the slot to be removed by grinding/sanding/filing or is one to think outside the box to achieve this result?

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 12:14 pm

by John kuehn

When I replaced the missing trim piece I used slotted flat head screws. I used the correct size drill bit and then countersunk the hole. I then installed the screws and ground them off smooth. I’m pretty sure it was originally done that way but thats my opinion.

The screws would need to be tightly secured and the slot head is needed to do that.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 1:03 pm

by Jerry VanOoteghem

John kuehn wrote: ↑Thu Jan 09, 2025 12:14 pm

When I replaced the missing trim piece I used slotted flat head screws. I used the correct size drill bit and then countersunk the hole. I then installed the screws and ground them off smooth. I’m pretty sure it was originally done that way but thats my opinion.

The screws would need to be tightly secured and the slot head is needed to do that.

Right. I believe the key is to not countersink so deep that the head won't protrude enough to grind away the slot. I suppose the slots & heads could also be covered over with body filler, but that might "pop" over time.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 3:44 pm

by JR Ewing

I’ll have to check some of the machine screw sizes I have and see how much of the slot, if any, seats below the tip of the trim. I never did pay much attention to how deep the countersunk areas of the trim is. It’s possible they could be shallower than what is normal depth in order to accomplish a smooth, slot-free, fastener. I appreciate all the replies.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 3:47 pm

by JR Ewing

Just for further reference, here is a picture of the drivers side panels that I removed from my 1918 Runabout.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Thu Jan 09, 2025 6:57 pm

by Harley_97

As John and Jerry both prescribed, flat head machine screws with a straight slot (10-24) but more importantly I'm in need of body wood.

Being that getting a hold of plans for 17-22 roadster body wood is no easy task, I'm wondering who has ordered wood or wood kits from either

https://fordwood.com/ or

https://www.classicwoodproductsllc.com/ what was your experience, is one better than the other?

Re: 1918 Roadster Seat Wood & Mounting

Posted: Fri Jan 10, 2025 9:43 pm

by JR Ewing

Thanks. Looks like that should work just as Ford planned.

Re: 1918 Roadster Seat Wood & Mounting

Posted: Fri Jan 17, 2025 12:13 pm

by JR Ewing

I have another question that I have not been able to find online or on this forum and it is regarding the top irons, not to be confused with the bows. The short irons that were in my 1918 Roadster connected the body at the tackstrip to the wood on the "B" pillar and did not connect to the seat frame area like others I have seen. Which irons are correct for my car. I did not see any part numbers on my irons but the parts book says the correct iron is part number 8401X, fits left and right sides and is for the years 1917-1922. Thoughts?

Thanks!