Page 1 of 1

New metal stem inner tube question

Posted: Sun Jun 01, 2025 5:18 pm

by KWTownsend

Do new Hartford 30x3-1/2" metal-stem inner tubes from Coker need bridge washers and nuts? Or can they be used like rubber stem tubes?

The old hardware has different threads and does not not fit the new tube stems.

It looks like the new tubes have the stems vulcanized, so is there a need for the bridge washers and nuts?

????

Re: New metal stem inner tube question

Posted: Sun Jun 01, 2025 6:16 pm

by Humblej

You do not need a washer and a nut in my opinion. The original clamp on stems used the washer and nut as part of the clamp, the washer is cupped to keep the nut away from the rim. A vulcanized metal stem is like a rubber stem inner tube.

Re: New metal stem inner tube question

Posted: Sun Jun 01, 2025 11:56 pm

by Steve Jelf

The old hardware has different threads and does not not fit the new tube stems.

Are you saying Hartford metal stem tubes now come with stems in the 777 size? Until now all modern metal stem tubes have had stems in the 724/725 size. Has the size now changed to 777?

https://dauntlessgeezer.com/DG110.html

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 8:59 am

by DanTreace

KWTownsend wrote: ↑Sun Jun 01, 2025 5:18 pm

Do new Hartford 30x3-1/2" metal-stem inner tubes from Coker need bridge washers and nuts? Or can they be used like rubber stem tubes?

IMO, the bridge washer and lock nut really adds strength to the stem tube interface. A lot of lateral force is on the tire when braking , which can move the stem. Locking the stem under the felloe and above with the companion washer /nut for the stem dust cover provides the necessary support to prevent tube / stem tear.

Yours looks like wire wheel brass stem, shorter type, on wire wheels, if under a higher powered chassis, the max protection for the tube may be best.

Wood wheel all metal felloe install:

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 9:51 am

by Oldav8tor

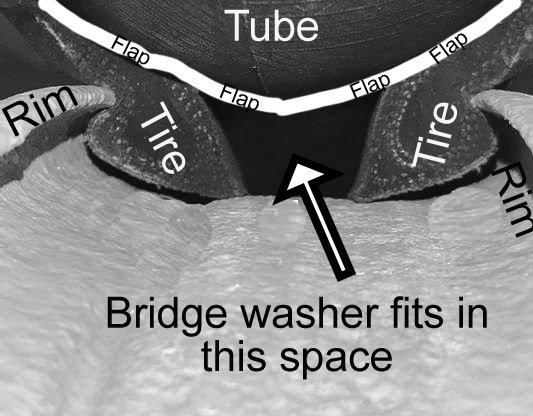

I use them - otherwise when you tighten the valve stem you can actually pull the tube down into the gap between the beads of a clincher tire. Like Dan says, it adds strength.

- Universal-T-Driver-Tire-on-clincher-rim.jpg (47.77 KiB) Viewed 6769 times

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 10:34 am

by KWTownsend

Tim:

Both diagrams indicate the stem goes through the flap, then the bridge washer and lock nut are installed (one diagram shows the stem pointing up, the other pointing down.) Correct?

Dan:

If you are a flap guy, do you concur on the order of assembly? Stem through the flap, then bridge washer and lock nut?

The tubes are for 30x3-1/2" tires. I don't know if they are wire wheel tubes or not. They belong to a friend of mine who had never mounter clincher tires before. My experience with the rubber stem tubes, that is the reason for my question...

Steve:

You asked:

Are you saying Hartford metal stem tubes now come with stems in the 777 size? Until now all modern metal stem tubes have had stems in the 724/725 size. Has the size now changed to 777?

I have no idea what the stem sizes are. I did not see any marking on the stem. I'm saying The old hardware has different threads and does not not fit the new tube stems.

: ^ )

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 11:16 am

by RajoRacer

I'm a flap guy and I've mounted dozens of 23" clinchers - I use the diagram that Tim posted above. The tube stem photo you posted above appears to be a Model A wire wheel tube ?????

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 12:07 pm

by Oldav8tor

The bottom photo shows the profile of the clincher tire, flap and tube in a clincher rim. If the stem were pictured it would be like the drawing with the flat of the bridge washer against the flap and the "Wings" bent towards the rim. I should point out that I've re-used flaps and tubes (Blockleys) and never seen any wear or damage around the valve stem using this method.

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 1:01 pm

by Steve Jelf

I have no idea what the stem sizes are.

I tried to describe them here:

https://dauntlessgeezer.com/DG110.html

The ⅜" and ½" listed are close enough to the actual sizes to be "Good enough".

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 1:02 pm

by ewdysar

I’ve got a new Hartford 30x3 1/2 TR383 tube here in my office with me. The stem is vulcanized to the tube. The bridge washer and lock nut were included in the box when received from Coker. The stem is unmarked, the bridge washer is marked “himile” and B5. I checked the thread of the lock nut which turned out to be M12-1.25 (edit - I was wrong, see post below), which could be surprising or not, given the modern world. I believe that the other hardware from Coker, i.e. rim washers and dust covers, should be compatible with these stems.

Keep crankin’,

Eric

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 1:16 pm

by RajoRacer

Over at Snyder's site, it appears the tube stem shown by Keith sports a #127 stem used on 23" wires !

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 2:54 pm

by ewdysar

I've been told that all Schrader stems and hardware are not a standard thread size, which is discussed in more detail in the following discussion:

viewtopic.php?f=2&t=36089&p=279598&hilit=12V1#p279598

While my measurement of M12-1.25 apparently falls within the manufactured tolerances (the lock nut is thin enough and has few enough threads to avoid binding on the thread checker), the bridge washer and lock nut on my tube are more likely to be Schrader 12V1 threads which are described in more detail in the aforementioned discussion. 1.25mm thread pitch works out to about 20-21tpi, the Schrader 12V1 pitch is 26tpi. Counting the threads with eyeball and utility knife, I roughly counted 25 threads in an inch which points to an actual 26tpi. I was surprised to see that when I googled "Schrader 12V1 tpi" there are taps and dies readily available on ebay

So I pulled a silver Schrader dust cap off of one of the wire wheels of my '27 Runabout. The big threads for the cap are part of the rim washer (the valve stem threads are smaller on wire wheel tubes). The cap threads on the rim washer are only about 6-7 threads total. When threading the cap directly on the brass stem seen in the photos, the cap threaded on smoothly until about 8 threads in to a sudden bind. It could be that the dust cap threads were never cleared deeper because there was no need. I believe that the the new tube stem, old Schrader cap, and rim washer are all 12V1.

Given all this, the new Hartford tubes should be compatible with new and old valve stem hardware matching the appropriate general Schrader size.

Keep crankin',

Eric

PS. thank you Scott for the lead towards this rabbit hole...

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 3:12 pm

by Steve Jelf

It must be the combination of my age starting with 8 plus my TBI that's making this so confusing for me.

The original posting describes the tube in question as a 30 x 3½ Hartford, with the metal stem vulcanized into the tube. Do I have that right? Then pandemonium enters the scene with the question of stem size. I'm familiar with stems of two sizes that were used in the Model T era. The valve stems used by Ford were about ⅜" in diameter. The wider stems used by many other companies are more common today, and are about ½" in diameter. So I'm left with this simple question: On Coker's new 30 x 3½ Hartford, with the metal stem vulcanized into the tube, is the metal stem ⅜" in diameter, or ½" in diameter?

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 3:41 pm

by ewdysar

Hi Steve,

My 30x3 1/2 T383 Hartford tube from Coker with the vulcanized brass metal stem for wood wheels, as shown in one of my posts above, is Shrader 12V1 which is almost 1/2" (apparently 12.2mm). This stem is threaded almost its entire length. From the Coker website "TR383 stem is brass stem 3 1/2 inch tall with 1/2 inch diameter at the base"

The silver stem shown in the first post appears to be a wire rim style metal valve stem which are typically Schrader 10V2 which is close to 10mm or 3/8". Part of the stem is necked down and smooth. From the Coker website "TR127 stem is threaded Nickel stem 2 1/4 inches tall, 3/8 inch in diameter at base."

The regular end of a Schrader stem, where you add the air is usually 8V1, close to 8mm or 5/16. This is what is found on almost every modern tire, and virtually all of the stems that we are discussing here.

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 3:52 pm

by DanTreace

Keith wrote:

If you are a flap guy, do you concur on the order of assembly? Stem through the flap, then bridge washer and lock nut?

The tubes are for 30x3-1/2" tires. I don't know if they are wire wheel tubes or not. They belong to a friend of mine who had never mounter clincher tires before. My experience with the rubber stem tubes, that is the reason for my question...

Yes. That is important order.

One caveat is using a flap.....be very sure...the flap hole is sufficient to allow the hex nut over the bridge washer to completely squish the flap and tube together. If the nut is loose, the flap can wiggle on the tube, and may lead to loss of pressure.

Photo shows flap over the tube in place in the tire casing. The bridge washer going on, and the hex nut following, and really torque tightly to get the thick rubbery flap to compress onto the tube, thereby making a real good seal.

Follow-on.....note the importance of the bridge washer hex nut to be very tight against the washer and tube to prevent leakage.

click on image to enlarge

This is the wire wheel metal stem, 30 x 3 1/2, used for that rim size wire wheel or disc wheel.

Re: New metal stem inner tube question

Posted: Mon Jun 02, 2025 9:45 pm

by Allan

What a mix up! Original metal stem tubes have a flange on the stem that is inserted in the tube. Then comes the bridge washer, with a raised land around the hole that is designed to add crush to the rubber pad on the tube. Then comes the stem nut to make that crush. This is all that makes the seal, and it has done so for ever. That is how Henry did it.

These new tubes have the stem vulcanised into the tube to make the seal. No bridge washer or stem nut needed. In fact, the bridge washer doesn't even have the raised land to add any crush. Properly tightened it can only displace rubber from around the stem.

Then comes the flap. The first drawing shows it fitted to the tube, and held there by the bridge washer and stem nut. That means the tube and flap must be installed as a unit! Then there is the concern that the bridge washer and stem nut needs to add further crush to make the seal that has already been made by the vulcanising of the stem. Or you can add the flap after the tube is inserted into the tyre. Or, leave the flap out altogether, like Henry did. Just work on the KISS principle.

I currently have six T's with clincher tyres. Some wheels have original threaded stems with bridge washers and stem nuts. Some have newer tubes to which I have added original threaded stems with bridge washers and stem nuts. Others have original or stick-on replacement rubber stems. One even has a brass valve extension on a short rubber stem. I use Dill valve covers with the sliding thread inside on all of them, because they fit on the small end of all valve stems. It probably comes as no surprise to some that none have flaps.

Allan from down under.

Re: New metal stem inner tube question

Posted: Fri Jun 06, 2025 10:17 am

by KWTownsend

Thank you for all the comments and guidance. My friend bought new bridge washers and nuts from Coker that fit his new tubes. This has been educational for both of us. It was my first experience with metal stem inner tubes and his first experience mounting clincher tires.

We got three of them mounted, but the rim on the fourth was pretty rusty, so he will sandblast and paint it before we continue.

Thank you!

Re: New metal stem inner tube question

Posted: Fri Jun 06, 2025 1:10 pm

by Original Smith

The new tire valve parts are garbage! Nothing has been done correctly! Do not buy any tubes unless they have rubber stems, which you can cut off and smooth to accommodate ORIGINAL valve stems. All the current manufactures are aware of this, and choose to do nothing! The Model A Club has.

Re: New metal stem inner tube question

Posted: Fri Jun 06, 2025 2:40 pm

by Steve Jelf

I haven't always agreed with Larry on fine details because I'm less strict about having everything correct. But we're together on this. We will continue to buy tubes with rubber stems and convert them to metal stems. He will do it for correctness, and I will do it for cheapness.

It's interesting that new metal stem tubes continue to have the stems in a diameter of about ½". As long as I have sufficient metal stems to replace rubber stems, and sufficient dust covers, I don't think I need to memorize any details of the current hardware.

Re: New metal stem inner tube question

Posted: Sat Jun 07, 2025 8:42 am

by Humblej

I agree, forget the modern metal stem tubes. Save some money and do it right. Buy a rubber stem tube, cut off the rubber stem and install an original clamp on stem. Easy to do.

Re: New metal stem inner tube question

Posted: Sat Jun 07, 2025 9:03 pm

by Allan

If the purpose of cutting off rubber stems to fit old brass ones is to be able to fit valve stem dust covers, use Dill covers with the sliding internal thread that fits the small end of all stems. You can leave the rubber stem in place until perhaps it gives trouble or gets sheared off when run at too low pressure. Then fit your replacement stem, and the same Dill covers. The old adage says, "If it ain't broke, don't fix it!"

Old time tubes had a thick pad of rubber, sometimes even fibre reinforced, where the valve stems were fitted. Newer tubes are much thinner. There is not so much rubber at the clamping point. If I ever have the need to fit a metal stem, I prefer to leave 1/8" of rubber from the old stem sitting proud of the tube surface so that when the stem nut is tensioned there is more rubber to squish when making the seal with the bridge washer. The bridge washer must have the ridge around the hole. many modern repops do not have this feature.

Hope this helps.

Allan from down under.

Re: New metal stem inner tube question

Posted: Sun Jun 08, 2025 12:54 am

by Steve Jelf

The purpose of buying rubber stem tubes and replacing the stems with old metal ones is to save money. Various original and reproduction covers will fit.

Re: New metal stem inner tube question

Posted: Sun Jun 08, 2025 1:03 am

by Allan

I get that Steve. Saving money is why I never use flaps. My point was there is no need to cut the rubber stem off until it gives trouble enough to warrant replacing it.

Allan from down under.

Re: New metal stem inner tube question

Posted: Sun Jun 08, 2025 8:50 am

by Humblej

Clincher tire changes are no fun, I do not want to do it more than necessary. I convert the innertube to a metal stem right off the bat and be done with it. I prefer the looks of the Schrader covers to the Dill covers but have to admit the Dill covers are pure genius.

Re: New metal stem inner tube question

Posted: Sun Jun 08, 2025 11:51 am

by Steve Jelf

Clincher tire changes are no fun...

The first time, or the first few times, it's a struggle for everybody. With practice, and with some study, it becomes routine stuff. No big deal.

Revelation: It's easier with the wheel on the car than off.

Re: New metal stem inner tube question

Posted: Sun Jun 08, 2025 9:13 pm

by Allan

Clincher tyres are not all equal. Some are far more difficult to fit than they need to be.

Much of the adverse reaction to fitting them comes down to an incorrect fitting technique. Three basic steps I follow are;

1. Fit the lightly aired tube into the tyre, sans flap.

2. Fit the valve stem through the rim hole and then BOTH sides of the tyre in the rim. Hold it there with a clamp or two. With non demountables fit the tyre up the same way with the valve stem at the bottom, and lower the car to hold it there.

3. Lever both sides on at the same time. Proper tyre fitting lube is your best friend.

I have now fitted four sets of Blockley tyres. They are a cinch, so much so that when I had fitted three of a set of five for a new club member, I handed over the fitting of the next two to him. Number four came with some instruction while he fitted number five while I was doing something else.

Hope this helps.

Allan from down under.

Re: New metal stem inner tube question

Posted: Mon Jun 09, 2025 1:11 pm

by Original Smith

I've got mostly Schrader stuff, but have some Dill and Bridgeport. Stick with the old stuff. You can use the old dust covers on the new valves, but why?

If you had the correct rim nut you wouldn't have to screw it down so far!

Re: New metal stem inner tube question

Posted: Mon Jun 09, 2025 7:31 pm

by Allan

There-in lies the beauty and practicality of the Dill covers Larry. You don't need any additional bits. Just screw them on the universal small end of any type of stem. One went "missing" on one of my cars the other day, so I just rat one of another car until I find a replacement. Just like screwing on any type of modern valve cover.

Allan from down under.

Re: New metal stem inner tube question

Posted: Mon Jun 16, 2025 4:48 pm

by Original Smith

I just checked the tire pressure on all four of my tires on my 13 roadster. It is so nice to know I'm using the original correct valve stems, and using an original Schrader inflator and an original Schrader pressure gauge too! It's just a good feeling!

Re: New metal stem inner tube question

Posted: Mon Jun 16, 2025 4:57 pm

by Tadpole

Original Smith wrote: ↑Mon Jun 16, 2025 4:48 pm

I just checked the tire pressure on all four of my tires on my 13 roadster. It is so nice to know I'm using the original correct valve stems, and using an original Schrader inflator and an original Schrader pressure gauge too! It's just a good feeling!

Larry, unless you’re running 777’s, you’re not running “original correct valve stems”!

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 7:04 am

by babychadwick

Just call AAA and tell them you have a flat and need the tire changed. When they arrive and take a look explain very clearly speaking very slowly that you said you had a flat tire and needed the tire changed, not that you needed a wheel replaced....

Problem solved

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 10:57 am

by Steve Jelf

How many hours will it take for somebody from AAA to each my rural location?

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 2:14 pm

by NorthSouth

-

Something that no one has mentioned thus far is that the modern Lucas inner tubes have tapered rubber valve stems that do not fit all the way through original wheel fellow holes. To have these modern valve stems fully seat in correctly the stem’s taper needs to be shaved down at its base. Has anyone else run into this problem or a solution less damaging to the valve stem?

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 2:31 pm

by Steve Jelf

I'm not familiar with tubes of the Lucas brand, but tapered rubber stems are no trouble if you replace them with Model T era metal stems.

https://dauntlessgeezer.com/DG110.html

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 3:03 pm

by RajoRacer

Bore out the rim hole to fit !

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 5:27 pm

by Original Smith

Something that Steve has overlooked, is the new rubber valve stems have had too large a base for over forty years! They have had to been filed down to fit through the rim to fit. Back in the early sixties when you could buy Monkey Ward, and Firestone tubes we didn't have that worry.

Re: New metal stem inner tube question

Posted: Tue Jun 17, 2025 7:45 pm

by Allan

I believe it is the rim hole which is too small for some modern rubber stems. By the time the tapered stem gets to the felloe hole there is plenty of room. I can see no reason why the rim hole can not be drilled a little larger to accommodate the thicker stem. With small original holes, rusty around edge, a new thicker, smoother edge may even be beneficial.

Allan from down under.

Re: New metal stem inner tube question

Posted: Sun Jun 22, 2025 2:22 pm

by Original Smith

I would never bore out the hole in the rim to fit those modern valve stems! It's easier to file or sand paper the base of the rubber stem to fit the tube. Whey mess up a factory rim? A little bit on ORIGINAL VALVE STEMS. Most of us know Ford used 777's from the factory. I have found from my experience that an 888 works just as good, and is 1/4" shorter. This doesn't affect anything except it may reduce the balance of the tire a bit.

Re: New metal stem inner tube question

Posted: Sun Jun 22, 2025 2:22 pm

by Original Smith

I would never bore out the hole in the rim to fit those modern valve stems! It's easier to file or sand paper the base of the rubber stem to fit the tube. Whey mess up a factory rim? A little bit on ORIGINAL VALVE STEMS. Most of us know Ford used 777's from the factory. I have found from my experience that an 888 works just as good, and is 1/4" shorter. This doesn't affect anything except it may reduce the balance of the tire a bit.

Re: New metal stem inner tube question

Posted: Sun Jun 22, 2025 8:25 pm

by Allan

With brass stems in tubes, new or old replacements, a rusted thin original valve stem hole in the rim is of no real concern. I would be concerned with an abraded down to fit rubber stem being used in such a rim. Tyre shops stock plastic sleeves use to adapt different size holes to different stems. I have used these on rusted thin stem holes in T wire wheels. On clincher rims they are never even seen. You can be safer without making any visible sacrifice.

Allan from down under.