Page 1 of 1

Question on a spring spreader

Posted: Mon Dec 01, 2025 12:43 pm

by LittleTimmy52

I need to do some more shenanigans on my rear suspension again. This time though I don't have access to the tools and shop i was able to borrow and hence can't replicate the janky definitely not OSHA approved method for spreading the springs. Would this model a spreader from Snyder's work on my 17 t? It's up there in my price range but I am no fabricator and I pay the price for lacking that skill.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 12:50 pm

by big2bird

I just use two blocks of wood.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 12:53 pm

by speedytinc

You don't need a spreader on a model T. Actually makes the job harder.

Using jacks & 2x4's under the leaf ends & Lifting against the body's weight will lengthen the spring to install the shackles.

My preferred method is to attach the perches first. Guide the perch stud into the backing plates. Pull home with the big castle nuts.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 1:32 pm

by LittleTimmy52

Wood might do it but I tried before and had no luck, though I think the blocks I used were too short. Side question, is that not bad for the axle all that weight?

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 2:04 pm

by speedytinc

LittleTimmy52 wrote: ↑Mon Dec 01, 2025 1:32 pm

Wood might do it but I tried before and had no luck, though I think the blocks I used were too short. Side question, is that not bad for the axle all that weight?

Use one jack on each side. (2 jacks) Or.......

I have A cradle I made that goes into my floor jack. Arms extend to either side to lift the axle by the end backing plate castings @ the same time.

Do not lift by the center pumpkin only.

Not that it wont work, but you will develop a gear lube leak & possibly bend the tubes.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 2:12 pm

by Steve Jelf

With the rear wheels off, loosen the perch nuts enough to relax the shackles. You should be able to leave the loose perches in the backing plates. There should be no need for blocks or a spreader.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 2:20 pm

by CudaMan

Here's how I did it when I installed my Ruckstell. Loosened the nuts on the spring perches, then used wood blocks to guide the spring eyes close enough to the perches to allow the shackles to slide in. Once the shackles were in, I re-tightened the spring perches.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 2:31 pm

by RajoRacer

I made one out of a 16" piece of 1/2" iron pipe, a 6" piece of 1/2" all thread, a couple 1/2" nuts & flat washers & a 1/2" coupler - grind down one end of the pipe just enough to go over one of the punkin bolts, heat up and flatten one end of the 1/2" coupler, insert the flattened coupler under the spring eye, insert all thread into the pipe, thread out the nuts until snug then wrench away to the desired length to insert the opposite shackle - I attach one shackle first then use the tool for the other side - I'll take a photo later.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 3:00 pm

by Jerry VanOoteghem

"CudaMan's" set-up is "spot-on". It can sometimes be slightly ticklish to find the sweet spot, where the spring is neither pushing nor pulling on the shackles to where you can slip the shackles in/out.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 3:56 pm

by Altair

I used some big U bolts around the frame and the spring and pulled it into place.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 4:06 pm

by Humblej

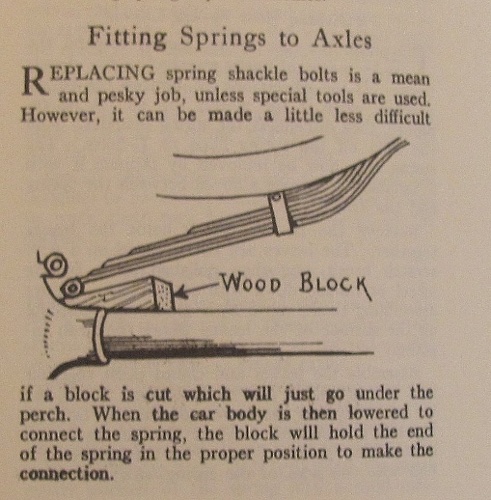

A spreader is not needed. The Ford Service Manual will show how to do it with wood blocks.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 5:53 pm

by DanTreace

Have used the taper wedge block method in the past.

- IMG_2164 (509x518) (491x500).jpg (130.17 KiB) Viewed 1048 times

But years ago got a custom made spreader from a retired guy who made some very nice Model T tools and replacement parts, spreader has sliding tubing over a large threaded rod to expand and contract the tubing on each end. Welded hump portion to clear the pumpkin and alignment stays, works so well it's the go to tool.

- spreader.jpg (71.99 KiB) Viewed 1048 times

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 6:23 pm

by RajoRacer

Here's my homemade contraption.

Re: Question on a spring spreader

Posted: Mon Dec 01, 2025 10:20 pm

by Wayne Sheldon

Over the years, I have worked on rebuilt replaced or put together so many model Ts, my own and helping other people, I have been through this probably dozens of times. I have used every method so far mentioned as well as a few others at times.

Model Ts are easy. Model A Fords? Not!

A long time ago, I was just recently out of high school, and most my personal interest was in era non-Fords. However, I had quite a number of good friends interested in model A and model T Fords. I had already developed a fair skillset in metal fabricating. A few of my close friends belonged to a local model A club, with a total membership of maybe about eighty families. There were a couple people in that club that had rear spring spreaders of their own, but were hesitant to loan them out, and the club itself had one rear spring spreader itself which was available to any member. The problem was, that with so many members, that one rear spring spreader was almost always being used, and the waiting list to "borrow" it was often out a few weeks (or months!).

One particular very close friend wanted to change the gears in his model A to a higher speed ratio, and the club's spring spreader was somewhere in the long list of members wanting to use it (it was often somewhere in the group hopefully to be found soon?). So I elected myself to gather some scrap metal, and buy a three foot long one inch coarse threaded rod and two new nuts to fit it. Then spent a couple hours cobbling together a rear spring spreader myself (even though I did not have a model A, however, I was considering getting one).

I went to my friend's home and helped him pull the rear end so he could change the gears. And later went back to help him put the rear end back into his model A.

I did shortly after buy a model A, and began restoring it, using the spreader on my project, as well as loaning it out to a few other friends and other club members. However, I quickly became more aware that the model A was just a bit too modern for me. I was getting much more involved with model Ts. Soon thereafter, I sold the less than half done model A to concentrate more on model Ts and other era automobiles. But I kept, and still have, the rear spring spreader. I have loaned it out a few times in recent decades, but often wish I had donated it to one of the model A clubs.

One of my model T speedsters had an altered rear spring that was a bit short, it was already that way when I bought the spring. It really helped installing that spring, although I am pretty sure one of the other mentioned methods would have gotten the job done had I not had the spreader.

Usually, I think I mostly just use the block of wood method to fit the rear spring together. Usually, they go together so quick and easy that way that there is nothing gained by even considering any other method. I have often just used a quarter inch thick scrap of wood a couple inches long to do the job.

One time, the quarter inch thick scrap of wood crushed and split under the weight of the spring and car. I had to waste a couple minutes to find another scrap and reset everything (no big deal).

Re: Question on a spring spreader

Posted: Wed Dec 03, 2025 12:29 pm

by LittleTimmy52

Well lucky me I did not need one. What I needed to get done was re centering the spring, I managed to monkey out the whole thing without taking it off the axle. I do appreciate the advice that everyone gave me because I will surely be using it come the day I have to take it off for whatever reason.

Partially off topic, if the bolt is centered and square to the hole (front what I can tell, if anything it's the smallest bit off on account of my finger not being an accurate tool) but won't go in would vibration of driving finish it getting it in place, or do I really have to take it apart again? For me anyways it's really difficult to manage despite everyone else having no troubles with the springs. If time and vibration can work that would be ideal.

Re: Question on a spring spreader

Posted: Wed Dec 03, 2025 12:33 pm

by LittleTimmy52

RajoRacer wrote: ↑Mon Dec 01, 2025 6:23 pm

Here's my homemade contraption.

Interesting, I wish I was more a fabricator my self, so many things I could make instead of buy. I lack tools and mentor and the money required for both.

Re: Question on a spring spreader

Posted: Wed Dec 03, 2025 1:59 pm

by Jerry VanOoteghem

LittleTimmy52 wrote: ↑Wed Dec 03, 2025 12:29 pm

... if the bolt is centered and square to the hole... but won't go in, would vibration of driving finish it getting it in place, or do I really have to take it apart again?

I guess it depends how close it is to fitting in place. However, if your clamps are tight, and the bolt head has not yet entered the hole in the frame, when it does, (by vibration or pure luck), your clamps will now be a bit loose. It really needs to be right. I guess you could use it for a while and keep an eye on things, looking for any changes in position, etc.