Page 1 of 1

Crank pully issues.

Posted: Sun Dec 14, 2025 10:56 am

by LittleTimmy52

So today I finally decided to pull the radiator off and start getting to work on some front end stuff I needed to do one of which being the crankshaft pulley, the PIN is a little messed up the hole on the crankshaft is wallowed out and the hole on the pulley is wallowed out, the crank handle also has a lot of wear on it. Is there anything that I could do to address all this slack and the crank handle without having to order anything? Also was there supposed to be 2 pads per side of the radiator? I have 2 new but pulled off 4 old. I don't have any fabrication tools so I can't really weld and grind things round. With my bad welding I'd make it worse, and it won't be round. Is there any way I can shim everything? The pin the holes etc? Also quick question on the washers there was a big one then the smaller one than the pulley is that correct?

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 10:56 am

by LittleTimmy52

These didn't upload

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 11:11 am

by TXGOAT2

Getting a better pulley and pin would help. The damaged crank stub is a problem. There are 2 piece crank pulleys available. It might be possible to use one of them with a slotted sleeve and an oversize pin to make a repair that would last a while.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 11:32 am

by LittleTimmy52

How well of a repair would JB weld and redrilling it be? I have a drill I can buy a drill bit and I can get JB weld but would it hold up enough?

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 11:42 am

by TXGOAT2

It would be very difficult to get a good repair using JB Weld on that. I don't know if the washers are supposed to be there.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 12:03 pm

by Kenny Edmondson

Just FYI… the washers are typically not there. Apparently there’s a lot of end play on the crank and someone’s made a fix to reduce that. It will probably continue to work, just need to keep it greased. .

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 12:22 pm

by Rich P. Bingham

Radiator rests on one leather pad each side.

Hard to tell how “wallered” the crankshaft stub is. That’s a problem. You could perhaps make an oversized crank pin if you have the right diameter stock. Upset the shaft with a punch or chisel to make it snug in the crankshaft.

If you have a large enough socket, you can use it to “shrink” the inside diameter of the pulley to fit snugly by hammering it over the pulley “thimble”. Another “fix” I have used is to file the end of the crank pin to fit into the opposite hole in the pulley, that can firm things up a bit.

I wouldn’t be too concerned about the wear on the crank handle, but if the bushing in the nose of the pan is badly worn, a new bushing will help a lot.

Mind, I’m suggesting shade tree “bandaids”, but model Ts can often go a long way on small remedies.

Good luck, and keep on enjoying your T !!

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 12:24 pm

by love2T's

Maybe this would work?

I got one on my '13 and its great.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 12:25 pm

by Dan Hatch

Have you looked at the bolt I circled? Looks loose.

- IMG_4845.jpeg (137.9 KiB) Viewed 1654 times

Also what year is this car?

Looks like pan is for large pulley. Those cars have spring system to mount radiator if I recall correctly? Dan

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 12:59 pm

by LittleTimmy52

It's a 1917 made at the end of july.

I used a monster can and shimmed it, it don't move anymore.

Here's some images of the mounting area. Also yes I fixed that loose bolt.

Also what should I do about my crank handle? I think for now I'm just going to leave it, I'll pick up a good old one somewhere some day.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 1:01 pm

by LittleTimmy52

This is kind of how it went on it's probably not original but again it will probably due if I can get more pads maybe or just use 1 per side.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 1:11 pm

by Mike Silbert

You have a bunch of issues going on there

1) Radiator mounting - there is supposed to only be one pad in there.

Now someone in the past may have added another one to get better hood alignment or fan clearance.

A lot of model T's are shimmed and tweaked to make things fit right. Parts get swapped, bent, sagged, worn and might just not quite right.

Vowel made a nice drawing of how Henry designed it.

2) The hand crank can be repaired if needed by several methods

It can be cut off and a new end added plus if it is slightly longer it wont hit the front license plate.

It can be welded on or pinned and brazed with a long lap

It can be sleeved or the worn areas welded up and recut.

Or get one that is in better condition.

If the crank is that worn the sleeve in the nose of the pan is probably in bad shape also.

3) The washers do not belong there and probably a "Farmer Fix".

I bet you will have to replace them or do something else like that.

4) The crank pulley pin is easy to make or buy a replacement

If you make on it can be customized to suit "abnormal" situations

5) The crank pulley can be replaced or sleeved or shrunk.

The pin holes can be redrilled 90 degrees off to make the holes "normal" again

Adjustable ones or 2 piece ones, possibly with a shim, might be a better fix.

6) The crankshaft nose - that is the tough one.

While a fix is best done with it removed (or replaced) and using a mill and a lathe if you are good it might be possible in the engine.

If the crank pin hole could be drilled cleanly oversized a custom sleeve could be made and pressed o restoring the pin hole to standard.

This is a risky procedure since making a mistake would lead to more trouble.

Maybe a 2 piece clamp on pulley would hold it tight enough for a while.

Filling the hole with JB weld might maybe work but the risk is that everything will get glued together.

Mike

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 1:19 pm

by speedytinc

Depends on how sloppy the pully fits on the crank. I dont have confidence in gluing the pully on with JB. It cant be distributed evenly enough. There is, however a locktite 660 that will fill the gap, designed to activate metal to metal. Designed for shaft wear & bearing fit on motors & industrial equipment.

Fantastic stuff. .010-.020" gap fill.

For minor looseness, green wicking lock tite will work. Look up the products working specs.

Either product requires both metal surfaces to be extremely clean & oil free.

As rich said - a slightly larger pin or flatten the center portion to press fit into the crank hole. Install in the correct direction & cotter pin.

Looks like a previous fix on a sloppy pully fit was to weld the pulley to the crank. Seen this before. Yikes!

Different radiator mounting hardware can be due to non original radiators or recored units that aint quite right. Try the correct pads

change/modify as needed for best hood fit.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 1:23 pm

by Plankhill

A better crank pulley with plenty of green loctite in the bore of the pulley not on the crankshaft. Let it set for two days. Loctite tha pin also.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 1:29 pm

by speedytinc

The leather pad will seem too thick because your frame has bolts holding it together instead of the correct rivets. Those bolt heads wont clear the small(rivet) clearance holes. One long thru bolt is way wrong & no flex for the radiator. Get the correct mounting hardware.

An aluminum can shim will loosen fairly fast. Not the best patch.

Consider steam cleaning that built up gunk layer.

This poor old T has been severely abused by "farmer" fixes over its life.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 4:24 pm

by Allan

Normally, the front face on the timing cover is just the rough surface of the casting. That cover appears to have been machined to give a flat surface. More intriguing is the front dam on the pan appears to have been machined also. How was that done? This could have been an attempt to limit end play in the crankshaft assembly. Hence the "thrust" washer.

Allan from down under.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 4:30 pm

by Jerry VanOoteghem

love2T's wrote: ↑Sun Dec 14, 2025 12:24 pm

Maybe this would work?

I got one on my '13 and its great.

This ^^^, 100%

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 4:31 pm

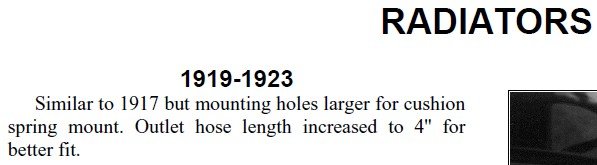

by Oldav8tor

I have a early 1917 - the radiator and shroud accept the later style of spring and thimble mount, not the leather pad. I don't know if it came that way or was changed later. The Vowell drawing you attached is more typical of brass radiator. A photo of the radiator and shroud mounts would be informative.

This is what I have

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 4:34 pm

by Mike Silbert

Is the polished smooth surface from years of the washers rubbing on it?

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 4:34 pm

by speedytinc

Could be the result of grit & oil behind that big steel thrust washer & a lot of run time.

As 1/2 a$$ed as the rest of what we see, I cant believe some skilled machine work was done in the past.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 5:59 pm

by TXGOAT2

I'm pretty sure that is wear from that big washer walking around the crankshaft.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 6:53 pm

by Mike Silbert

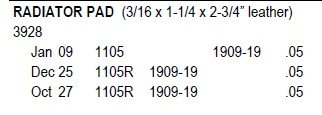

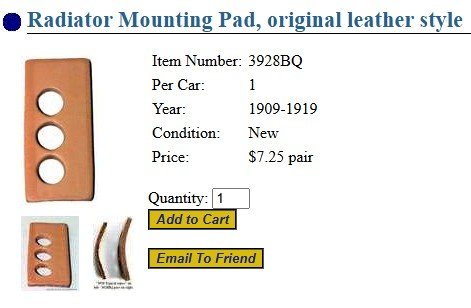

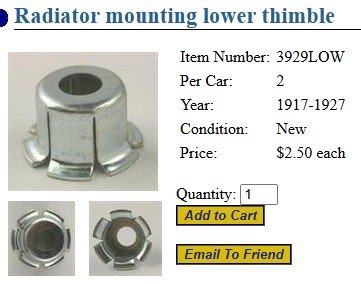

I had always assumed that the 1917-1927 cars had the spring mounted radiator until I looked it up

The judging guidelines say nothing about the radiator mounting

The Vowel drawings say that in 1917 it is mounted like a brass radiator car

The Encyclopedia parts listing says the leather pad is used to 1919

- Screenshot 2025-12-14 173816.jpg (10.66 KiB) Viewed 1511 times

Just like Langs says

- Screenshot 2025-12-14 174018.jpg (24.86 KiB) Viewed 1511 times

The encyclopedia radiator description says the 1917-1918 radiator is different from the 1919-1922 with a smaller hole and no thimbles

- Screenshot 2025-12-14 175121.jpg (18.39 KiB) Viewed 1511 times

I am confused as to why Langs also lists the thimbles as 1917-2927 ?

- Screenshot 2025-12-14 175755.jpg (23.18 KiB) Viewed 1511 times

Snyders lists the thimbles as being 1917-27 and 1919-27 on exactly the same page!

Chaffins has spring mounted as starting in 1920

I thought it was cut and dry but yet again I found a contradiction.

I guess it all comes down to the size hole is in the radiator and shell.

As far as his original problem goes, to make a reliable touring car the engine should come out and be inspected for other "special" features

If he just wants to stay local and not go far or fast a quick patch up might do.

The last one I worked on like that got a different crankshaft, pulley, babbitt, pistons, rings, a new drum, different cam, new valves, and more

Looks like a full barrel of snakes to me.

Mike

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 7:04 pm

by John kuehn

The washers were probably put on behind the pulley to help take up any pulley looseness.

Replace the crankshaft pulley and pin, the bushing in the nose of the pan and if you can find a better hand crank that’s even better.

The crankshaft nose might be OK without fileing or carefully grinding off the ding on the end of it.

When you see and maybe hear things going on in your engine you have to make a decision on how far you want to go in repairing the engine. If it’s still running well don’t go any farther with it. In the end it comes down how much you want to spend on the engine and eventually on a rebuild.

Re: Crank pully issues.

Posted: Sun Dec 14, 2025 9:59 pm

by 1925 Touring

I'll add, make sure you have a cotter pin in the crank pully like it is designed for! I was driving in one of our cars and had the crank pully work loose and hit hard against the nose of the pan. I thought I had a rod go thru the block or something, it sounded terrible! It eventually fell out and I gingerly drove the car home. I never found the pin, and theres a scrape in the nose of the pan. It's fixed now. The crank hole was snug and I replaced the crank pulley with a good used one, the old one was loose on the crank. I ordered a new pin from Lang's and made sure I had a cotter pin in!

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 9:48 am

by DanTreace

The repro modern fan pulley with split and set screw fastener is the best method, plus it is flanged to keep the flat fan belt in place.

Lots of nice features, as the set screw tightens the pulley on a worn crankshaft. And use the pin too for the crank handle ratchet to bite on. Be sure to allow room for the ratchet to grab by keeping the retaining cotter pin at the edge.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 10:22 am

by LittleTimmy52

So the general consensus is get the right mounting hardware for the radiator and the pulley is way wrong. Is there supposed to be any gap between the pulley and the engine? If it's not supposed to have washers and the face supposed to be rough, I'd assume so. In that case then I'll try and get a hold of that fancy split pulley.

The last owners did some real cheap jobs on this t. And it's now at my expense. Oh well.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 10:35 am

by LittleTimmy52

as for the cross member bolts, there supposed to be rivets, can/should I take those bolts off and put rivets? I think langs sells them, do I need some special riveter? and where else should I look to see if I have bolts in place of rivets?

Edit: Never mind, I lack both the will and the torch to hot rivet anything, the bolts stay., maybe I can just round them and make them look like rivets to fit.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 10:38 am

by jab35

Lucas:

Is the magneto functional? My guess is removing that washer will result in it working less well. At least check the endplay in the crankshaft before completing the work. Good luck, jb

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 10:43 am

by LittleTimmy52

jab35 wrote: ↑Mon Dec 15, 2025 10:38 am

Lucas:

Is the magneto functional? My guess is removing that washer will result in it working less well. At least check the endplay in the crankshaft before completing the work. Good luck, jb

functional, yes it is. Question, how do I check that? can it be done with minimal disassembly?

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 11:23 am

by Mike Silbert

You can grind SOME of the thickness of the bolt heads for the front crossmember to make the radiator fit better.

It would also maybe require bigger holes in the pads (if you even need them) but it is easy to punch leather.

Or you could just leave the radiator sitting slightly high with thicker pads, if things align well enough.

Fit and Finish was not one of one of the best features of the Model T but they were generally not horrible.

This is a judgment call on where to go.

Checking the end play on the crank when it is installed in the car:

With the car in park, neutral, low or reverse the clutch linkage is pushing the crank forward so there will be no end play here.

So while someone watches to see if it moves move the parking brake forward and drop the transmission into high.

If it moved then the measurements will be not honest.

Measure the distance from the front of the crankshaft to a fixed point

Push or pry the crankshaft rearward and measure the distance again.

Ideally this should not be a noticeable distance (less than 1/64" of an inch) and only 3 to 7 thousandths of an inch.

See:

viewtopic.php?t=44314

You can also open up the lower inspection cover and in high gear pry the crank back and forth.

If you are in the bottom check for shims and loose areas everywhere.

There are some patch things that can be done if the heart is still in good shape.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 11:38 am

by Oldav8tor

Regarding the radiator mount - It would be interesting to know what is on the Rip Van Winkle 1917....

I replaced my original round tube radiator with a reproduction - they didn't ask me when I ordered it what kind of mount it used. That said, It's possible the original radiator was replaced with one slightly newer for some reason....they would have had to replace the shroud too. The hole in the shroud is too good not to have come from the factory that way.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 1:01 pm

by RajoRacer

Here's an original '17 with the factory fan shroud - pretty rare.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 1:18 pm

by big2bird

They do make " rivet bolts." They have a rivet head on a bolt. I made my own, but they do exist. It makes that area less congested, and buys time for if/ when you do a frame off.

Re: Crank pully issues.

Posted: Mon Dec 15, 2025 4:21 pm

by big2bird

As for the crank pin, I drilled the end of my crank, threaded the hole, and installed an Allen set screw. 50 years, and the pin has never moved/ rattled around.

Re: Crank pully issues.

Posted: Thu Dec 18, 2025 10:40 am

by LittleTimmy52

you know those brass end play shims, can I use one of them with my outside oil line? one of the 2 bolts it uses is replaced with the oil line would it leak if I undo it enough for the shim? should I cut one of the ears off and only have the 1 bolt hold it?

also update: I am buying the radiator mount for the year later as my radiator is not the right one it has the 1 big hole not the 3 little ones, and I will take a dremmel to the bolt heads to make em more rivet like, and on top we are getting new radiator hoses clamps (the current ones are not the best) and a spark plug (1 leaks compression from rust, I can only afford 1). My small reserve of money i set aside for T parts will now be gone.

I wish I could fix the farmers fixes but until the coffers have more than a penny and a fly, the plethora of farmers fixes through out the car will stay. its not rigged its "character" I like to say. actually, if you think about it, its more period correct, the farmers fixes and my poverty that is.

On a serious note, the rigged junk will be fixed right someday, thanks everybody.

Re: Crank pully issues.

Posted: Thu Dec 18, 2025 3:26 pm

by Mike Silbert

Lucas,

Here is my style and attitude:

"Farm Fresh" Model T's are also an important part of the history just like perfectly restored cars and original reference examples.

A lot of the story of these cars gets lost when they get restored to perfection.

But sometimes they have to be restored to save them.

My favorite car to drive is full of a lifetime of battle scars and even is bent from when the barn fell on it.

It looks bad enough that typically once a year someone asks me how I got it there.

It blows their mind when I hand crank it up and it purrs like brand new, its too hard to push a Model T.

There are only a couple of things I push for are safety (as safe as reasonable), reliability (if it breaks down all the time its no fun), and it looks like a period complete package that belongs together.

Do the best you can with what you have and go have fun

Ok, I will get off my soapbox and back to your project.

Brass end play shims:

They can be tricky to install and cause some problems. They can rock when tightening the bolts making them hard to fit. If you want to use one get it all to fit properly before reassembling the radiator and front of the car. Verify that it is not too tight after tightening. Fit it with a real bolt before going to the oil tube. I would not use only 1 bolt in the shim. You need the pulley properly in place before fitting the shim.

The oil tube fitting:

These are fragile and have been known to break or strip. If it were my problem then I would use a bolt that fits, drill and tap it making a custom part. If you can not do this then find a local club member that can help. Depending on your setup how the fittings work have to be figured out.

Radiator Mounting:

Only the center hole is used to hold the radiator down, the outer 2 holes are only there to clear the rivet heads. Make the frame rivets (bolts) fit through the pad holes and the pads be slightly higher than the fasteners. The radiator and shell should only have one hole in it and it probably correct. If there is a small hole mount it like an early car, if there is a large hole mount it like a later one.

Spark Plugs:

Run the best ones you can and don't worry about it. There is a tone of personal preference, I reserve Champion X plugs (Big $) for show cars. Proper plugs is a hotly debated topic. A good timer is important but good coils are very important. I have run mismatched plugs for years and even the dyno could not tell. One of these days I will remember to fix it.

Radiator Hoses and Clamps:

They often do not reseal or cause issues so no surprise here

Re: Crank pully issues.

Posted: Thu Dec 18, 2025 5:21 pm

by TXGOAT2

A car needs to start and run dependably. Breakdowns and won'tstarts out on the road are no fun. Safety, including good braking, steering, brakes, tires, wheels, and all related parts, has priority over cosmetics, cushions and accessory doo-dads.

Re: Crank pully issues.

Posted: Fri Dec 19, 2025 2:32 am

by Gleaner

speedytinc wrote: ↑Sun Dec 14, 2025 1:29 pm

This poor old T has been severely abused by "farmer" fixes over its life.

Farmers are pretty smart fellows. I would like to see some Orange County California fixes!