Page 1 of 1

How to remove welded castle nuts

Posted: Mon Dec 22, 2025 12:00 am

by CornFed T

I’m getting ready to remove the front axle on my ‘17 touring, and I noticed that someone has welded the castle nuts on the bottom of the spring perches where they go through the radius arms. I can’t really get a wrench or a socket on it to try and break it loose. The only form of heat I could put on it would be a MAP gas torch, but I don’t know if that would do anything. Does anyone have any suggestions?

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 1:17 am

by Mark Chaffin

You could try carefully grinding the weld down flush with the top of the castle nut. Apply heat to the weld and try breaking the nut loose.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 5:56 am

by Wayne Sheldon

Mark Chaffin wrote: ↑Mon Dec 22, 2025 1:17 am

You could try carefully grinding the weld down flush with the top of the castle nut. Apply heat to the weld and try breaking the nut loose.

I would second that suggestion as a first effort.

Question? Is that a secondary wishbone/brace with the above axle perches original for 1917? The studs were somewhat shorter on those perches than the ones on the later style perches. That brace (?) appears to be thicker than were many of the added braces. It may be that someone welded the nuts into place because the stud was too short to get a cotter pin in place. If that is the case, it may not take much grinding to eliminate enough of the weld for it to break free. Regardless, plan on destroying the nuts! No worries, they are a standard thread and easily replaced

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 7:53 am

by Allan

Wayne is onto it. It looks like a later wishbone has been fitted to over-the-axle wishbone perches which were standard on a 1917 model. They have used a standard castle nut to attach it rather than the correct nut with a taper on be back to seat in a corresponding countersink in the under-axle wishbone eyes. So the nut was not engaged deep enough to be able to fit a cotter pin. You can grind on the nut as suggested. Don't go so far that you compromise the cotter pin hole in the perch. Once ground down, the remaining weld may just break free.

Alternatively, once you have tried the grinding trick, you might try splitting the nut. That too, may help crack the welds.

Good luck.

Allan from down under.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 9:01 am

by John kuehn

When attempting to grind off the weld try to grind off just enough to remove the weld.

Remember that grinding off to much you’ll lose the length of the perch where the cotter pin goes through.

But if that happens you can use a lock washer to secure another nut.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 9:13 am

by ThreePedalTapDancer

Yes, grind down the weld. A hand held grinder with 4-1/2 60 grit flap wheel will do the job quickly. I’ve removed many bugger weld safety additions over the years.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 9:34 am

by big2bird

Just saw the nuts off. The perches are already trash.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 9:48 am

by TXGOAT2

You may find that the holes through the axle are worn oversize and out of round. The nuts can be ground or filed back to get them off.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 10:59 am

by Rich P. Bingham

Thought - I’d presume you would remove the axle, radius arms and all before “doing battle”. I, too, doubt the perches will be worth saving.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 11:58 am

by RajoRacer

Tight spot would be good use of a Dremel w/H.D. cut-off wheels - just nip off the weld on the top of the nut to be able to get the proper wrench on the remainder of the nut & loosen ?

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 12:11 pm

by Erik Johnson

The car in question has the later perches.

Click on the link below see a photo of it. The, click on the photo for a larger view.

viewtopic.php?f=2&t=50197&p=378150#p378150

PS: Not all 1917 Fords are actually 1917 Fords. Right off the bat, I see things that indicate it is not a 1917 Ford:

- later horn button

- thimble mounting system for radiator and shell

- fluted headlight lenses

- later front perches as previous mentioned

- no crease/bulge in splash apron

- later front fenders (1924/25 style)

- square felloe rear wheels and demountable front wheels

Assuming the car is not a "put together" and the engine is original to the car, if the original poster provides the engine serial number and more photos of the car, he will find that helpful for any future questions or endeavors.

Some of the above could have been changed at any time. For example, if it truly started out as a 1917 from the factory but the front end was damaged in an accident, that would explain the much later front fenders, the thimbles on the radiator shell, fluted headlamps, etc.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 1:10 pm

by JTT3

I like Allen’s idea of splitting the nut. You can use a flat punch & a BFH USING THE PUNCH AT THE SPLIT. It may peel it off.

Re: How to remove welded castle nuts

Posted: Mon Dec 22, 2025 5:18 pm

by Mike Silbert

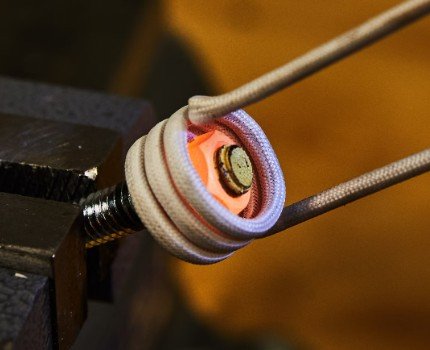

If (when) you heat the nut use an induction heater.

- Screenshot 2025-12-22 171019.jpg (24.17 KiB) Viewed 1352 times

While I love and am quick to grab a torch, an induction heater is really handy.

Carefully remove as much weld as possible without ruining the perch before heating.

It might be junk already, but I like to inspect it first.

Re: How to remove welded castle nuts

Posted: Tue Dec 23, 2025 11:08 am

by Charlie B in N.J.

The weld doesn't look too deep in the photo so as some suggested I'd use a grinder first. Of course there's a possible under lying problem which is why it was done in the first place.

Re: How to remove welded castle nuts

Posted: Wed Dec 24, 2025 5:02 pm

by Stephen_heatherly

I would suggest taking the wishbone and axle out from under the car together as an assembly. With the axle out, it'll be much easier to grind the weld off the nut. The spring perches are more than likely in poor shape and will need to be replaced anyway, so I wouldn't be too worried about damaging them.

Stephen

Re: How to remove welded castle nuts

Posted: Wed Dec 24, 2025 6:00 pm

by Steve Jelf

Thus far nobody has mentioned this, so I will. After you get the axle off the car and the welds removed, you may find the perches absolutely stuck solid in the axle, as they often are. You can loosen a stuck perch by clamping it in a vise mounted on a heavy bench. After soaking the shaft with a good penetrant, use the axle as a long lever to break it loose from fully stuck. This may be easy, or it may require repeated attempts with more penetrant before the perch is ready to come out.

Re: How to remove welded castle nuts

Posted: Thu Dec 25, 2025 3:02 am

by Allan

And if Steve's tip does not do the trick, heating the axle beam at the perch holes will help. Just don't try hauling on the axle while it is red hot. The only time I have done this was with a ruined axle, and it didn't matter if the perch holes opened up as the axle bent.

Allan from down under.

Re: How to remove welded castle nuts

Posted: Thu Dec 25, 2025 12:15 pm

by 1925 Touring

Don't be surprised if your spring perch looks like this. On my project T someone had welded the wishbone itself to the bottom of the axle. The weld had broken and the nuts were loose, so mine were easy to remove.

Whatever you do, good luck!

There's a reason someone welded those nuts to the bottom, and it is a good idea to fix it! The vendors sell very nice spring perches for $60. Money well spent in my book. The front axle and wishbone take a lot of sudden hits from bumps in the road.

Re: How to remove welded castle nuts

Posted: Fri Dec 26, 2025 9:53 am

by Jerry VanOoteghem

Has anyone noticed that the OP seems to have left the building?