Page 1 of 1

Engine Mounting Bolts

Posted: Tue Jul 16, 2019 9:38 am

by Oldav8tor

It's clear from what I've read that the bolts that go horizontally thru the frame and wood block are not to be tightened beyond the point where they don't rattle but what about the top bolts? Same thing? Snug? Tight? I've been researching but the answer isn't clear. Thanks!

Re: Engine Mounting Bolts

Posted: Tue Jul 16, 2019 10:06 am

by DanTreace

Tim

The frame top rail to pan bracket short bolts are

tight! No wiggle, drawn down tight and insert cotter in the castle nut on top.

The top ones are fastened first, before you place the wood blocks into the frame rail.

The longer side bolts, placed into the wood blocks, are drawn up snug, not loose, but don't pull them so tight as the top ones. Like to finger tight, then wrench only enough to align the cotters for inserting. With the

snug, you should be able to turn the head of the long bolt against the frame rail, and the castle nut with cotter should gently twist with it.

Re: Engine Mounting Bolts

Posted: Tue Jul 16, 2019 2:21 pm

by Oldav8tor

Thanks Dan

As someone who taught high school science for 34 years, I got used to answering the same questions over and over. It requires patience and a smile..... I appreciate

your patience and that of other forum members when the same questions keep coming up. Please know that we newbies appreciate it!

Re: Engine Mounting Bolts

Posted: Tue Jul 16, 2019 3:04 pm

by RustyFords

I'm about to install an accessory engine support (aka belly-band) that came with a parts chassis.

It's secured to the frame via the horizontal bolts. Do the same procedures about tightening apply with the belly-band added?

Re: Engine Mounting Bolts

Posted: Tue Jul 16, 2019 4:42 pm

by DanTreace

Tim

You are welcome, that little detail is also noted in Ford Service, paragraph 100.

The belly bands are just added support for the engine crankcase already mounted. So yes, install the T engine factory way, wood block motor mount at pan, with both bolts, and be sure the wood block inside the frame to the inside of pan arm is tight, you want to have to knock that block in place.

Takes strain off the arm, as the whole engine will twist in the chassis with braking and low pedal acceleration.

Note the marks of the arm on the inside of an original wood block, was fitted very snug to get this impression.

Have those belly bands also, can't hurt and may help keep me out of the 2-piece crank club

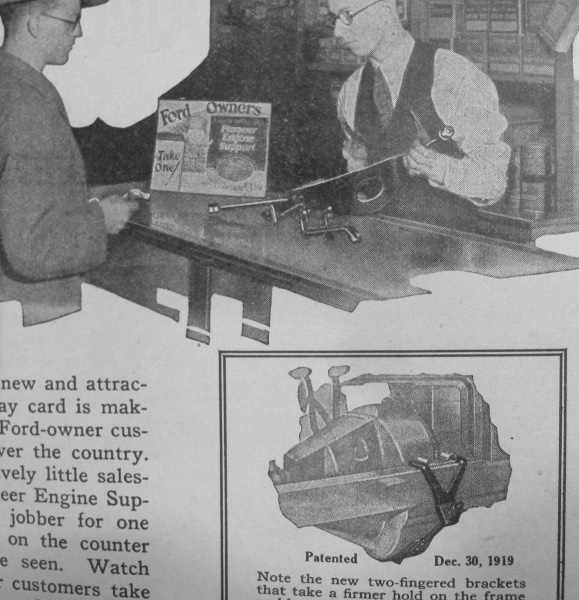

- IMG_0718 (800x600) (580x435) (579x434).jpg (142.75 KiB) Viewed 4959 times

- IMG_0369 (579x600).jpg (169.92 KiB) Viewed 4959 times

Re: Engine Mounting Bolts

Posted: Wed Jul 17, 2019 7:05 am

by It's Bill

This newbie sure appreciates the info! I will be pulling and replacing my engine this Fall, and I had no idea about the different tightening specs. I guess I should read the instructions...

Maybe the guys who have been at this for a while and know these details could put together a book called something like "The Fine Points". I would buy it!

Cheers, Bill

Re: Engine Mounting Bolts

Posted: Wed Jul 17, 2019 10:11 am

by babychadwick

Dan-

If the top bolts are taken up tight before installing the wood blocks why is the top of the block cut to hold the bolt head while tightening?

Re: Engine Mounting Bolts

Posted: Wed Jul 17, 2019 10:21 am

by JTT3

Not sure but I thought that was for a space to run wiring.

Re: Engine Mounting Bolts

Posted: Wed Jul 17, 2019 10:40 am

by MWalker

The top of the wood block is notched so it will clear the bolt head when you insert the block. The bevel at the bottom of the block creates a space where the gas line runs.

Re: Engine Mounting Bolts

Posted: Wed Jul 17, 2019 10:51 am

by Dropacent

As belly bands were brought up, I think it’s a good idea to apply a thin rubber surface between the pan and band. The ones we manufacture have a thin neoprene pad glued on.