Page 1 of 1

Switch work

Posted: Thu Nov 05, 2020 3:08 pm

by Rich Eagle

It all started when my Coupe ignition switch would not turn. It was an old switch that worked with the wrong key but was what I could find when I built the Coupe. My first move was to take the back off and clean everything. I find that a chisel works well for prying the tangs back. Things were clean inside except for some WD40 I sprayed in the hole. That’s probably not good for the fiber parts inside. The back end of the tumbler cylinder had part of it broken off but no loose pieces were present. Someone had been inside before. Perhaps Me.

The composite back plate was somewhat warped. I tried to straighten it by relieving holes for the contacts in some hardwood and then putting pressure from a press on it for a couple of days. This didn’t help noticeably. Some soaking of the tumblers without disassembling was done and then I put the switch back together in case I decided to reuse it.

The next effort was to try and get another switch to work. This one had a good cylinder although the tumbler plates were rusty. I took them apart keeping track of which went where and cleaned them as best I could. I ordered keys for this one and some others but not wanting to wait I tried to make a key. That did not work and I didn’t want to tweak the plates to make it work.

Re: Switch work

Posted: Thu Nov 05, 2020 3:11 pm

by HPetrino

"Someone had been inside before. Perhaps Me." Hahaha. Yup. Maybe so. That's how it goes past a certain age.

Re: Switch work

Posted: Thu Nov 05, 2020 3:12 pm

by Rich Eagle

While waiting for keys I decided to look into making parts for my favorite switch, an early die cast handled one.

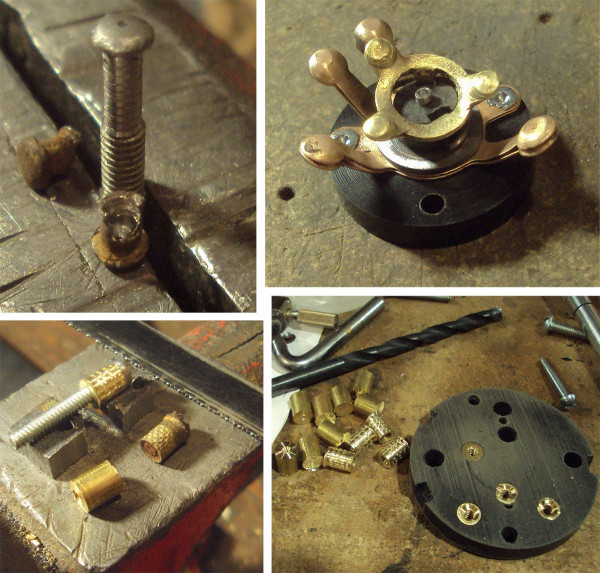

The contact assembly unscrews from the handle on these. I drilled the rivets and disassembled the tumblers and cylinder and soaked the parts in solvent. Cleaning the handle revealed a number and fortunately I had that key for it. I had to figure out the order and orientation of the tumbler plates which took a while.

The plug between the tumbler and contacts and the ring that holds the light contacts needed to be refabricated. I had some Delrin round stock which worked well for those. I used the rivet holes to mount the delrin to a wooded block in the lathe for machining the light ring. There were two bronze contact spiders for the lights. I suppose it was to get more spring pressure

New rivets were made from #8 screws for attaching the contacts to the light ring. A .099 nail worked for riveting the ignition plug washer although a bit tedious drilling a hole into the center of it. I made the back plate from a plastic material found at the Army/Navy store. Not Delrin but perhaps nylon or something. It didn’t machine quite as nice. I turned some brass slugs and threaded them. The originals had a knurled surface to keep them from turning. I hammered a hacksaw blade into them to serve the same purpose. Back together that switch works well

I had already put the first switch in the car and will use it until it gives more trouble. Meanwhile the new keys came. The one for the second switch does not go in the hole so the cylinder must be warped. I think I can do a little filing to make it go. I also ordered a new tumbler with keys so I can refurbish one more switch assembly. All previous attempts in years past to repair switches had not gone this well or been this fun. I suppose that means something but I’m not sure what.

Rich

Re: Switch work

Posted: Thu Nov 05, 2020 3:31 pm

by Rich Eagle

P.S. I just went back to see if I could make the second switch work. It is a #57 and the new #57 key won't go in. However an old #54 and #66 work just fine in it.

Go figure.

Rich

Re: Switch work

Posted: Thu Nov 05, 2020 4:34 pm

by Dallas Landers

This winter's to do list includes working on the switch in the TT Rich. It loses contact on the mag side going down the road. I know I have the Apco explosion proof muffler but it scares the buggy horses while racing.

I fixed the one in my pickup. Hope to be lucky twice.

Re: Switch work

Posted: Thu Nov 05, 2020 4:44 pm

by D Stroud

Dallas, is that the same switch I had on it? Dave

Re: Switch work

Posted: Thu Nov 05, 2020 5:09 pm

by John kuehn

Wow! I learned something today. Didn’t know the die cast earlier switch had the more complicated switch back and parts. Thanks for sharing! I can understand why the later versions have been copied for reproductions. But the earlier one like Rich shows don’t know about that one!

Re: Switch work

Posted: Thu Nov 05, 2020 5:18 pm

by Dallas Landers

Yes it is Dave.

Re: Switch work

Posted: Thu Nov 05, 2020 5:44 pm

by Rich Eagle

I have two other types of early die cast switches. The one with internals and back plate has a poor handle. I couldn't find any information about any of these. There may have been some posts on the forum. If I could find pictures of what the one on the left looks like I might try to make them work. It's housing is much deeper that the right one.

Apparently there were at least 3 vendors.

Does anyone have info?

Rich

Re: Switch work

Posted: Thu Nov 05, 2020 7:16 pm

by RajoRacer

The cast handle switches came on the scene in 1919 with the electric start crowd. They also used the intricate ammeter movement meter.

Re: Switch work

Posted: Fri Nov 06, 2020 12:16 am

by Steve Jelf

I love the new back plate with the home made brass slugs.

I've used coarse sandpaper to flatten a warped back plate.

Re: Switch work

Posted: Fri Nov 06, 2020 12:31 am

by D Stroud

Dallas, I took that apart and cleaned it up, it was in very good shape. I just snugged the contacts up a bit and put it back together as I recall. I annealed the tabs that hold it together, so it should come apart fairly easily. That was only about twenty years ago or so, I MAY have forgotten something though.

Dave

Re: Switch work

Posted: Fri Nov 06, 2020 6:56 pm

by Rich Eagle

This housing has 2 screws a little to one side to hold the back cover on. That leaves a gap on one side. The tab that lines up with the notch is for positioning. There are 3 of them placed around the housing. I soldered an L-shaped piece on with a screw to put pressure down on the side where the gap was. It's not pretty but it won't show and the switch body will still go through the hole. The red/brown disc I made first but as it was a little warped from age I didn't use it. It left a gap too. I may put inserts in it and replace the black cover.

Also shown is the brass connecter between three inserts. They allow one wire from the battery as each one energizes a different circuit.

I ordered a larger piece of Delrin today. It will make some nicer back covers for other switches.

Re: Switch work

Posted: Fri Nov 06, 2020 7:36 pm

by Jerry VanOoteghem

Rich Eagle wrote: ↑Fri Nov 06, 2020 6:56 pm

This housing has 2 screws a little to one side to hold the back cover on. That leaves a gap on one side. The tab that lines up with the notch is for positioning. There are 3 of them placed around the housing. I soldered an L-shaped piece on with a screw to put pressure down on the side where the gap was. It's not pretty but it won't show and the switch body will still go through the hole. The red/brown disc I made first but as it was a little warped from age I didn't use it. It left a gap too. I may put inserts in it and replace the black cover.

Switch8.jpg

Also shown is the brass connecter between three inserts. They allow one wire from the battery as each one energizes a different circuit.

I ordered a larger piece of Delrin today. It will make some nicer back covers for other switches.

Rich,

I like your L-Shaped bracket & screw idea. Reminds me of my 1989 Mustang. Part of the ignition switch fell apart. It had tabs, similar to the T switch, that were supposed to hold everything together... but they didn't. I solved the problem by making a special little C-Clamp that held the contact assembly together. Worked great. A few years later, Ford recalled those Mustangs due to those switches falling apart and starting fires. Just for fun, I took mine in for the recall. When I went to pick it up, the service manager asked me to wait for the mechanic to speak to me. He highly praised my little invention and we had a good laugh over it! He kept the switch & clamp as a souvenir.

Re: Switch work

Posted: Sat Nov 07, 2020 1:25 pm

by Rich Eagle

That's wonderful that they were impressed by your bracket. This 2 screw system was quickly replaced by the 3 pin or 4 tab system. Perhaps the 3 or more different die cast type switches were just different vendors. I just don't see how 2 screws could hold that cover tight without being 180° from each other.

Re: Switch work

Posted: Sat Nov 07, 2020 7:16 pm

by Rich Eagle

For what it's worth I found this post by George John Drobnock. His odd, single switch looks very much like this one I am working on. That would make it a Briggs & Stratton.

http://www.mtfca.com/discus/messages/50 ... 1438226631

The funny tabs and two screws were discussed there. Some other posts suggest Dan Trace is an expert on these. I may try and contact him.

Rich

Re: Switch work

Posted: Mon Nov 09, 2020 1:25 pm

by Rich Eagle

After some digging I thought I would post what I have found on the die cast (handle) switches. The one I have been working on (at left) is a Briggs & Stratton as I mentioned thanks to George John Drobnock's post. The other two I have are Clum switches.

Dan Trace identified them as 1919 & 1920. Both have provisions for 3 pin back plate.

I believe the center Clum switch had internals like these.

Later switches used the 3 pin back plate and then the 4 bent tab housing took over. There are differences in the switch handles. The earliest used a prong that was bent over the square insulating ring. later ones just used notches. The early housing and handle shown center here came out of an early (1920?) dash. I have seen the later style handle in the 3 pin housings so apparently those changes happened at different times. The later handle is captured by the plates that are riveted together. The earlier one is not captured and can come out with the tumbler assembly when the prongs are bent back.

There is some good information buried in past posts but it is scattered and sometimes hard to find.

Rich

Re: Switch work

Posted: Thu Nov 12, 2020 3:17 pm

by Rich Eagle

This switch back plate has an extra contact. Circled in red it appears it would connect with the coil contact when the ignition switch is in the off position. I am baffled as to what that would accomplish. Also, (highlighted) above the mag contact reads SIDE. This was a 3-pin plate with the early "bend over" tabs on the switch handle. I'm guessing late '20 or so. Also interesting was a nickel plated stand-off spool on the coil contact (center).

Apparently the 3 pins had failed as there were 2 holes drilled through the switch plate and one remaining make shift retaining bracket.

Does anyone have a clue or is it just one more curiosity in the game?

Rich

Re: Switch work

Posted: Thu Nov 12, 2020 4:43 pm

by John kuehn

Would like some advice. Have you tried to straighten or decompress the fiber/ masonite switch backs that have warped or come apart?

I have one that isn’t in bad shape other than being a little warped.

Can you soak them in water to soften them, then decompress and use some type of sealer or glue to hold them together after they dry?

Thanks for any help.

Re: Switch work

Posted: Thu Nov 12, 2020 5:03 pm

by Rich Eagle

While searching for answers I found this post by Mark Osterman 3 years ago. It may help.

http://www.mtfca.com/discus/messages/70 ... 1511749949

I did try to straighten one overnight in the press with poor results. I have thought of what you say but not sure what glue to use.

Re: Switch work

Posted: Thu Nov 12, 2020 5:46 pm

by John kuehn

Thanks Rich on the update on Mark O’s post! Yes it seemed to me the switchback material could be softened and pressed back together. Thanks to Mark for the instruction tips about how to do It.

Re: Switch work

Posted: Thu Nov 12, 2020 6:51 pm

by Duey_C

Had a backing plate that the layers were separating around the locking pin. Put on some CA/crazy glue liquid, stuck it in the vise, opened and closed it to help the glue get IN the layers, added a little more glue, gently set the vise just snug and left it overnight.

Nice and solid the next day. Filed/sanded the excess and put it back to work.

Well, after another two nights that is. The other two were coming apart also.

Cool thread Rich!

Re: Switch work

Posted: Sat Nov 14, 2020 12:28 pm

by Rich Eagle

In making the square insulator that links the switch handle to the contacts plate I needed to determine how wide to make the slots for the tabs. The remaining cardboard insulators I have are too distorted to measure. When I started measuring the tabs on both handles and contact plates I found different widths on them. They varied from just over 3/8" to just under 5/16". They are shown here with 3/8 at left and 5/16 a right. 3/8 seemed to be the early bend over type. Two contact plates had .360. Most of the handles were 5/16. This may have been a variance in the suppliers. I guess I will custom fit each insulators to the parts I am using.

I'm not sure play in these parts are a good thing.

Rich